CLOSE

About Elements

TANAKA is a leading company in the field of precious metals.

Advanced materials and solutions that support societal progress, the development stories behind them, the voices of engineers, and our management philosophy and vision—

Elements is an online media platform that shares insights that lead to a better society and a more prosperous future for the planet under the slogan “Mastering Precious Metals.”

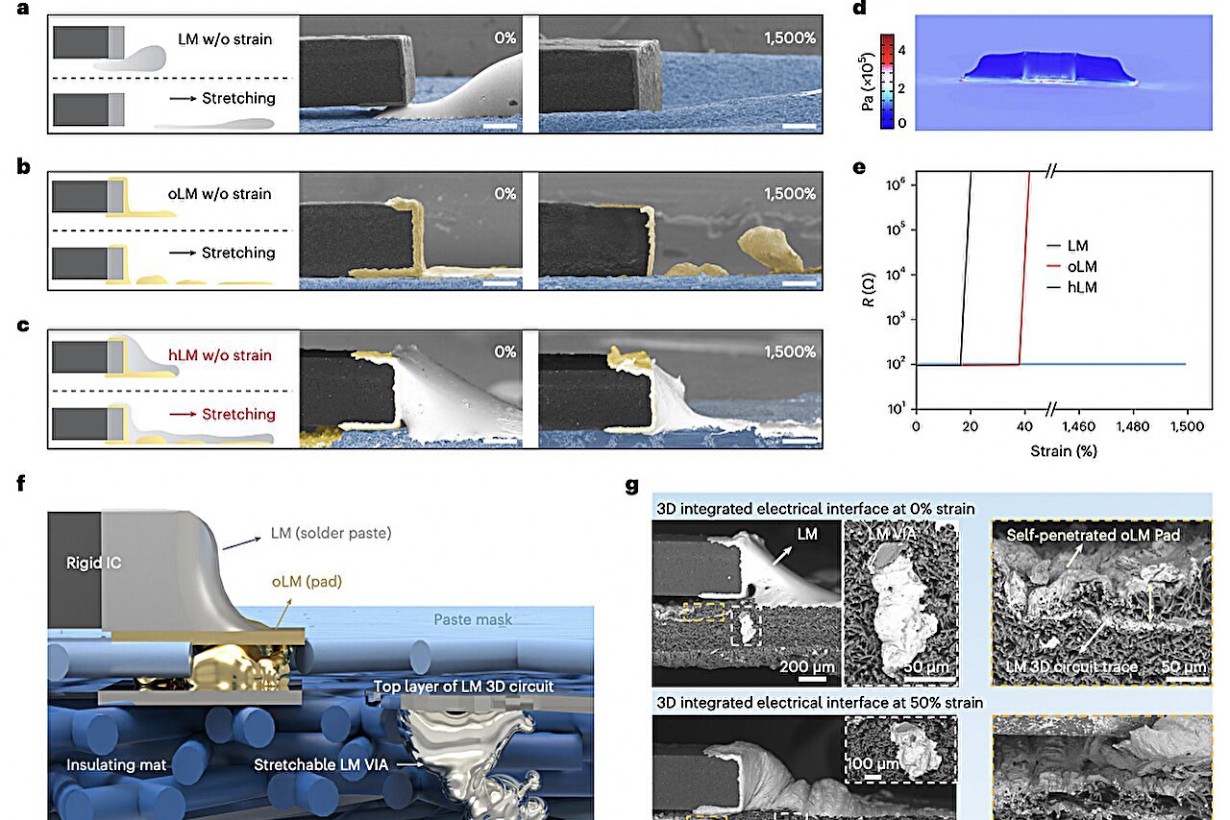

Flexible, permeable and 3D integrated electronic skin combines liquid metal circuits with fibrous substrates

In recent years, research teams worldwide have been trying to develop new flexible and soft electronics. These devices could have various potential applications, for instance helping doctors to monitor their patients’ health conditions or supporting rehabilitation and performance sports.

To be safely and comfortably worn by users daily, these devices should be permeable (i.e., based on breathable materials that allow liquids and gases to pass through them). They should also be bio-compatible (i.e., safe to be worn on the human body for long periods of time) and strain resistant, meaning that they do not break easily when stretched or pulled in a specific direction.

Researchers at the Hong Kong Polytechnic University and other institutes in China recently developed a new intrinsically permeable, 3D integrated and flexible electronic skin. This e-skin, presented in a paper in Nature Electronics, is based on high-density inorganic electronic components placed on organic stretchable fibrous substrates.

“Most stretchable electronic systems have low-density integration and are wired with external printed circuit boards, which limits functionality, deteriorates user experience and impedes long-term usability,” Qiuna Zhuang, Kuanming Yao and their colleagues wrote in their paper. “We report an intrinsically permeable, three-dimensional integrated electronic skin.”

Instead of utilizing impermeable and rigid printed circuit bords, Zhuang, Yao and their colleagues used a skin-like multilayered circuit board based on stretchable and permeable materials. This micropatterned circuit board is made of liquid metal and fiber mats.

“The system combines high-density inorganic electronic components with organic stretchable fibrous substrates using three-dimensional patterned, multilayered liquid metal circuits and stretchable hybrid liquid metal solder,” the researchers wrote. “The electronic skin exhibits high softness, durability, fabric-like permeability to air and moisture and sufficient biocompatibility for on-skin attachment for a week.”

The new stretchable material developed by the researchers was found to be highly resistant to strain, retaining its electrical properties up to an impressive strain of 1,500%. Moreover, the electronic skin can let both air and moisture pass through, preventing rashes and skin inflammation after being worn for long periods of time.

When they compared their proposed material to a previously developed stretchable electronic skin based on the material polydimethylsiloxane (PDMS), the team found that it was significantly thinner and less rigid. To further demonstrate its performance, the researchers used their electronic skin to develop bio-electronic devices that can record and wirelessly transmit physiological signals to another device.

“We use the platform to create wireless, battery-powered and battery-free skin-attached bioelectronic systems that offer complex system-level functions, including the stable sensing of biosignals, signal processing and analysis, electrostimulation and wireless communication,” the research team wrote.

In the future, the inherently permeable and flexible electronic skin developed by this team of researchers could be used to fabricate a wide range of devices for the reliable and safe monitoring of physiological processes. In addition, it could inspire the design of similar bio-compatible devices based on flexible circuit boards and liquid metal solders.

※Top Image: Reliable 3D hybrid interfaces using ultrastretchable hLM solder. Credit Zhuang et al.

This article was written by Ingrid Fadelli from Tech Xplore and was legally licensed through the DiveMarketplace by Industry Dive. Please direct all licensing questions to legal@industrydive.com.

![]()