CLOSE

About Elements

TANAKA is a leading company in the field of precious metals.

Advanced materials and solutions that support societal progress, the development stories behind them, the voices of engineers, and our management philosophy and vision—

Elements is an online media platform that shares insights that lead to a better society and a more prosperous future for the planet under the slogan “Mastering Precious Metals.”

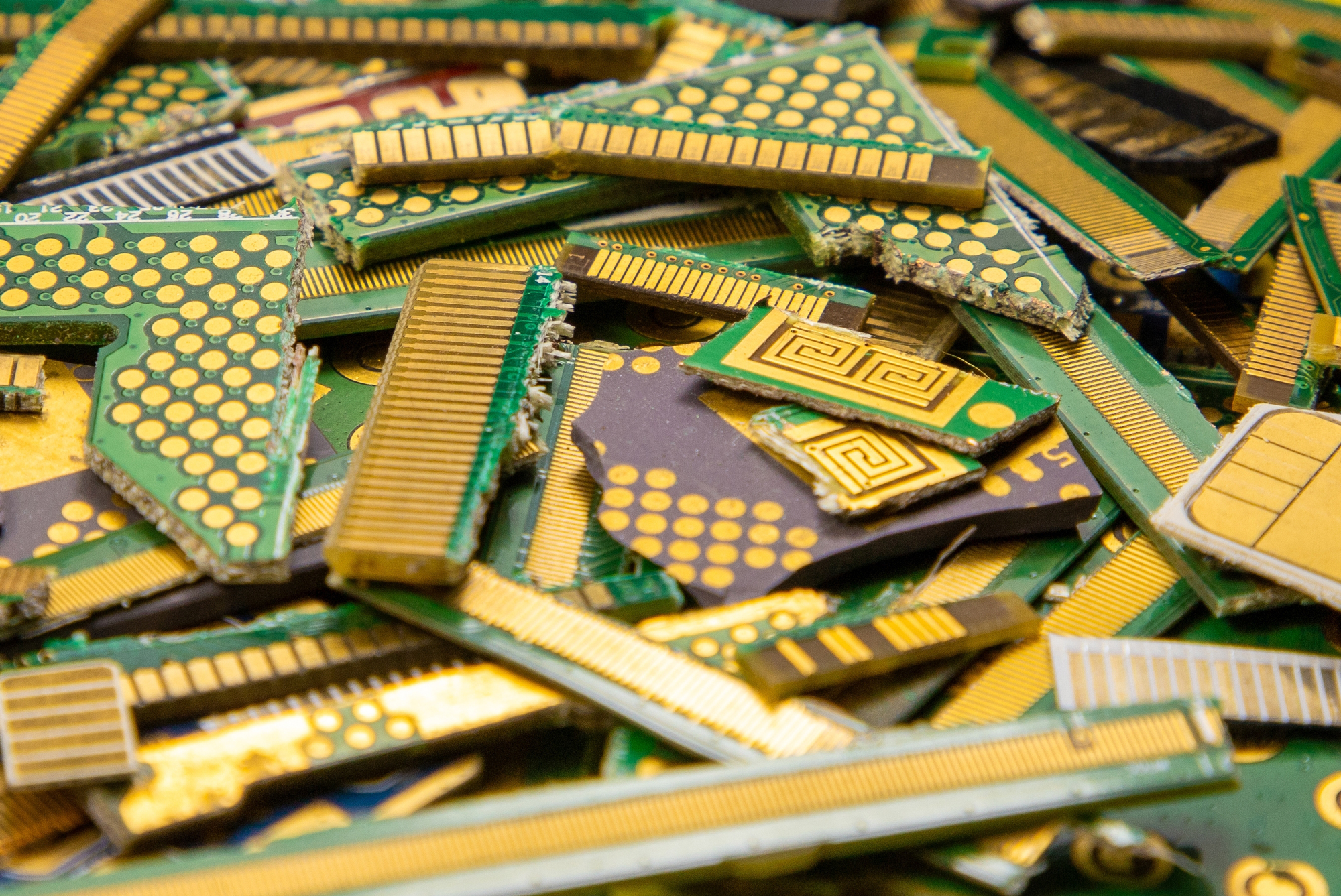

First-person Perspective: Factors point to more recycling of precious metals

Sebastian_Photography/Shutterstock.

by Bodo Albrecht E-Scrap News

This article appeared in the 2024 issue of E-Scrap News. Subscribe today for access to all print content.

There’s one very simple, unavoidable reason that global industry is at least eventually going to have to rely more heavily on recycling in order to satisfy its seemingly ever-growing demand for precious metals for its products: Several of the major mining operations around the world are in advanced stages of their life cycles.

Already, for example, South Africa’s mines are being dug 2 and 3 kilometers deep. Precious metals are a finite resource, and — given today’s rising dependance on them in a range of products — we can envision shortages of gold, iridium, osmium, palladium, platinum, rhodium, ruthenium and/or silver coming in the decades ahead. New sources are being explored, but they come at a high price.

That is only one of the reasons, however. There are multiple other factors that portend change for the precious-metals landscape. They all point to more recycling and recovering of the precious metals that already are within industry’s grasp.

The Environmental Factors

There has been a study performed twice by the International Platinum Group Metals Association, a nonprofit association which represents leading mining, production and fabrication companies in the platinum, palladium, iridium, rhodium, osmium and ruthenium industries. Member companies have been surveyed on the carbon output of their recycling processes for platinum-group metals, which are produced from the same ore mined primarily in Russia, South Africa and North America. The result was so shocking in the first run that it prompted the IPA to undertake the study a second time with greater scrutiny. The findings grew even more dramatic the second time around: Recycling can reduce the carbon output of precious metals by more than 90% versus mining.

“Effective strategies for end-of-life management of equipment containing PGMs must be established to minimise collection losses and ensure every gram of PGMs can be reused,” the IPA later wrote. “There is also scope for improved collection of the metals from existing applications to boost the recycled supply of these metals. Policies improving the collection of end-of-life PGM-containing equipment are essential to help to maximise recycling.”

Even when we think of the relatively large energy input demanded by some of the recycling processes that are employed around the world, those processes still contribute only a minute fraction of the carbon footprint compared to the use of heavy machinery and equipment in mining precious metals.

Furthermore, recycling is such a more efficient method to attain the resource. It varies depending on the vein of the ore, but about 1 ton of mined gold ore typically can be expected to yield about 5 grams of gold. On the other hand, 1 ton of cell phones, about 10,000 devices, can yield up to 280 grams of gold.

![]()