NEWS/RELEASE

TANAKA PRECIOUS METAL TECHNOLOGIES Develops Miniaturized Micro Profile, a Next-Generation Contact tape for Fifth-Generation Signal Relays

Achieving a tape width of 0.2 mm for contact tapes to enable smaller relays

March 12, 2025

TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd., a company engaged in the industrial precious metals business of TANAKA, announces the development of its miniaturized micro profile tape, a next-generation contact for fifth-generation signal relays. It has achieved a minimum width of 0.2 mm, making it the smallest-sized contact tape for fifth-generation signal relays. As relays become smaller, using miniaturized micro profiles can make contacts lighter in weight and suppress bounce and chattering*1 during the opening and closing of contacts. Shipment of this product’s samples is scheduled to start in late March 2025.

Miniaturized micro profile (Contact tapes)

Micro profiles are ultra-small contacts used in relays and switches, which are the signal control components in electronic devices. Relays are components that take in external electrical signals and carry out the opening and closing or switching of electric circuits. They are widely used in a variety of devices, such as those for communications and facilities and consumer electronics. Contacts embedded in relays responsible for the opening and closing of electric circuits require a high level of reliability as they may cause wrong operation or malfunction of devices if they do not operate properly.

In recent years, the miniaturization of electronic devices has led to an increased demand for smaller relays. As relays shrink in size, the weight of the contact that causes bounce during opening and closing has become a significant issue. It is believed that bounce can be minimized by using smaller and lighter contacts. By reducing bounce, electrical signals can be controlled more accurately, which helps to prevent malfunctions in devices. Additionally, smaller contacts contribute to resource savings by reducing the amount of precious metals used, ultimately lowering costs. TANAKA has successfully developed miniaturized contacts through years of research and development in precious metal materials, along with advanced processing technology.

■ Next-Generation Contact for Fifth-Generation Signal Relays

Since entering practical use in the 1830s, relays have been embedded in various electronic devices. Relays that control larger signals using relatively smaller signals (contact opening and closing current of up to 2 A) are called signal relays. Research and development of signal relays and contacts have progressed together with the development of electronic devices, with relays and the contacts inside them becoming smaller.

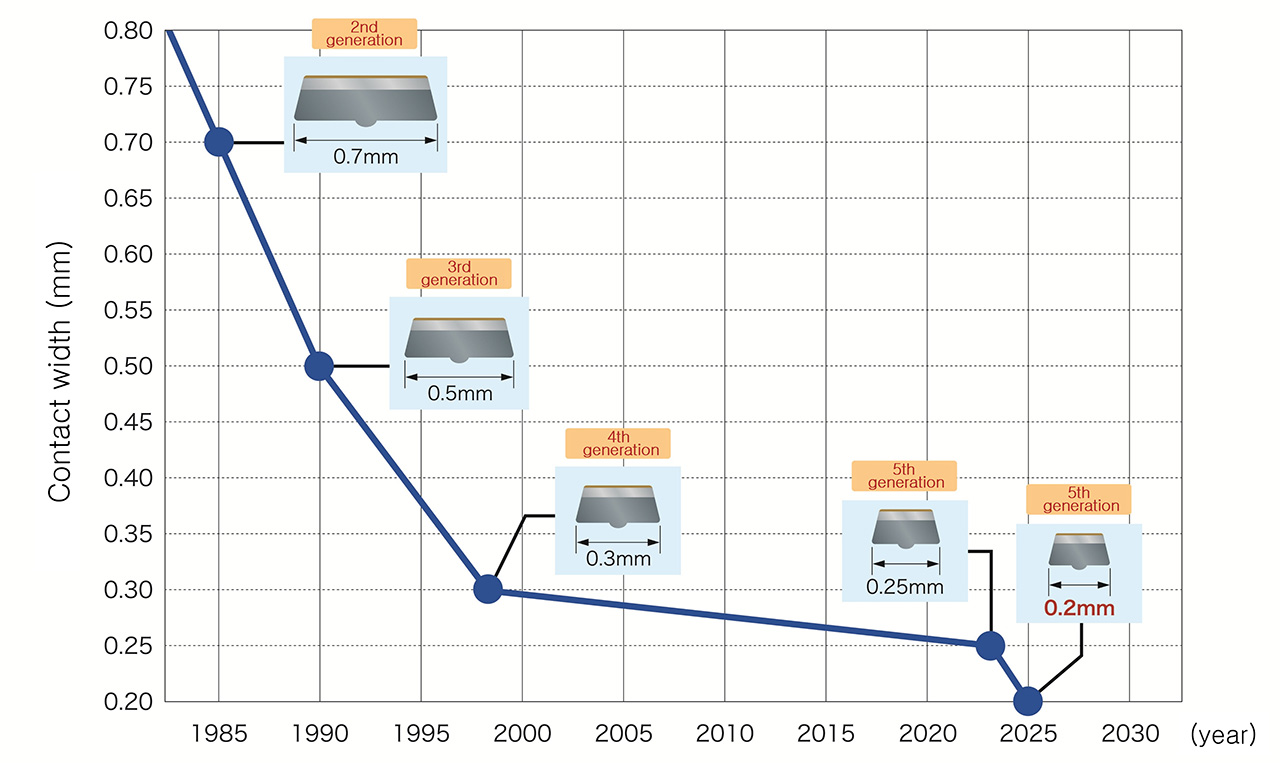

TANAKA has been developing contacts for signal relays since the 1970s, succeeding in developing contacts (0.3 mm tape width) for fourth-generation signal relays in 1998 and contacts (0.25 mm tape width) for fifth-generation signal relays in 2023. Fifth-generation signal relays are used in various fields requiring a high level of reliability, such as communication devices, semiconductor inspection equipment, medical devices, network cameras, smart consumer electronics, and automobiles.

History of signal relay contact miniaturization ※Based on research by TANAKA

■ Miniaturized contact that is compatible with various materials and methods

The miniaturized micro profile contact tapes of TANAKA is compatible with various materials and methods. Multilayer contacts using different types of metals are available for a wide range of electric loads and are achieved through employing unique precision bonding techniques.

<Features of micro profiles (contact tapes)>

- Allows multilayer bonding of different types of metals

- Contact tape with excellent bonding strength across its entire length

- Allows reduced sizes of relays and switches

- Various contact materials, shapes and thickness are available to suit a variety of applications.

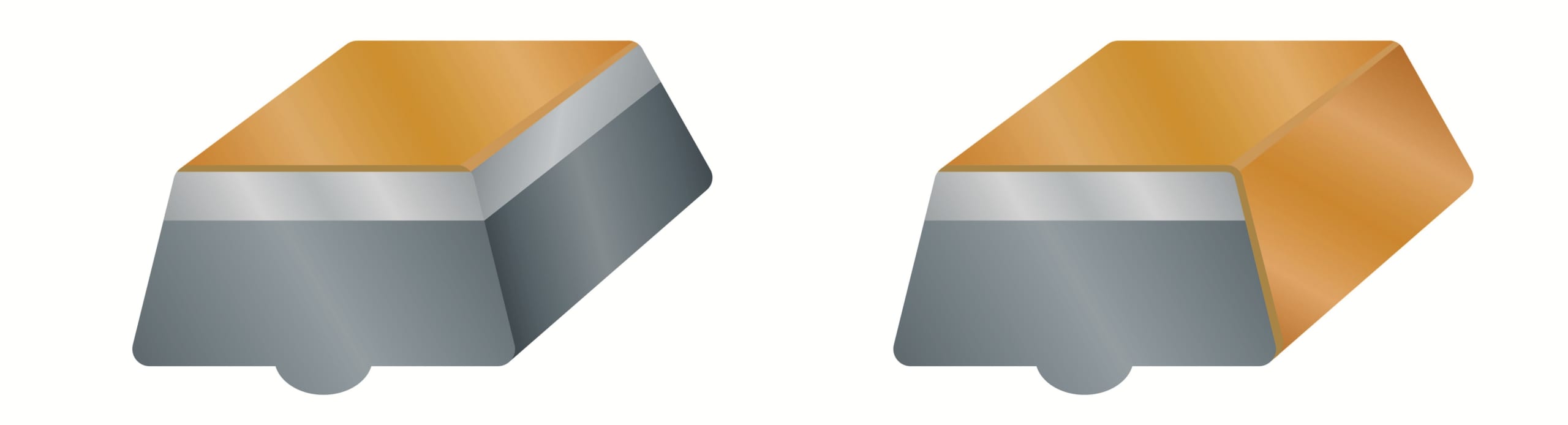

- Method for forming the gold (Au) layer on the surface can be selected depending on the desired properties (cladding or sputtering)

Cladding (left) and sputtering (right)

_________________________________________________________________________________________

*1 Both bounce and chattering are undesired phenomena in switches and relays, where the unintended opening and closing of contacts may lead to wrong operation. Bounce refers to the phenomenon where, due to shock during contact opening and closing, the contact jumps and repeatedly opens and closes. Chattering refers to the phenomenon of repeated opening and closing due to external vibration and such.