NEWS/RELEASE

TANAKA PRECIOUS METAL GROUP Announces Business Partnership with JEPLAN to Realize a Decarbonized, Circular Society

– Framework for Treating Organic Materials (Plastics) in Precious Metal Recovery Processes –

July 31, 2025

TANAKA PRECIOUS METAL GROUP Co., Ltd. has decided to enter into a business partnership with JEPLAN, INC. (Headquarters: Kawasaki City, Kanagawa; Representative Director, President, and Chief Executive Officer: Masaki Takao; hereinafter “JEPLAN”) to reduce CO2 emissions and promote the recycling organic materials in the precious metal recovery processes of TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd., a company engaged in precious metals business.

This initiative represents a collaboration between TANAKA, committed to advancing a circular economy in the precious metals field, and JEPLAN, which has been pursuing similar goals in the plastics field, with both companies aiming to achieve a decarbonized, circular society.

■TANAKA’s Initiatives Thus Far for Realizing a Circular Society

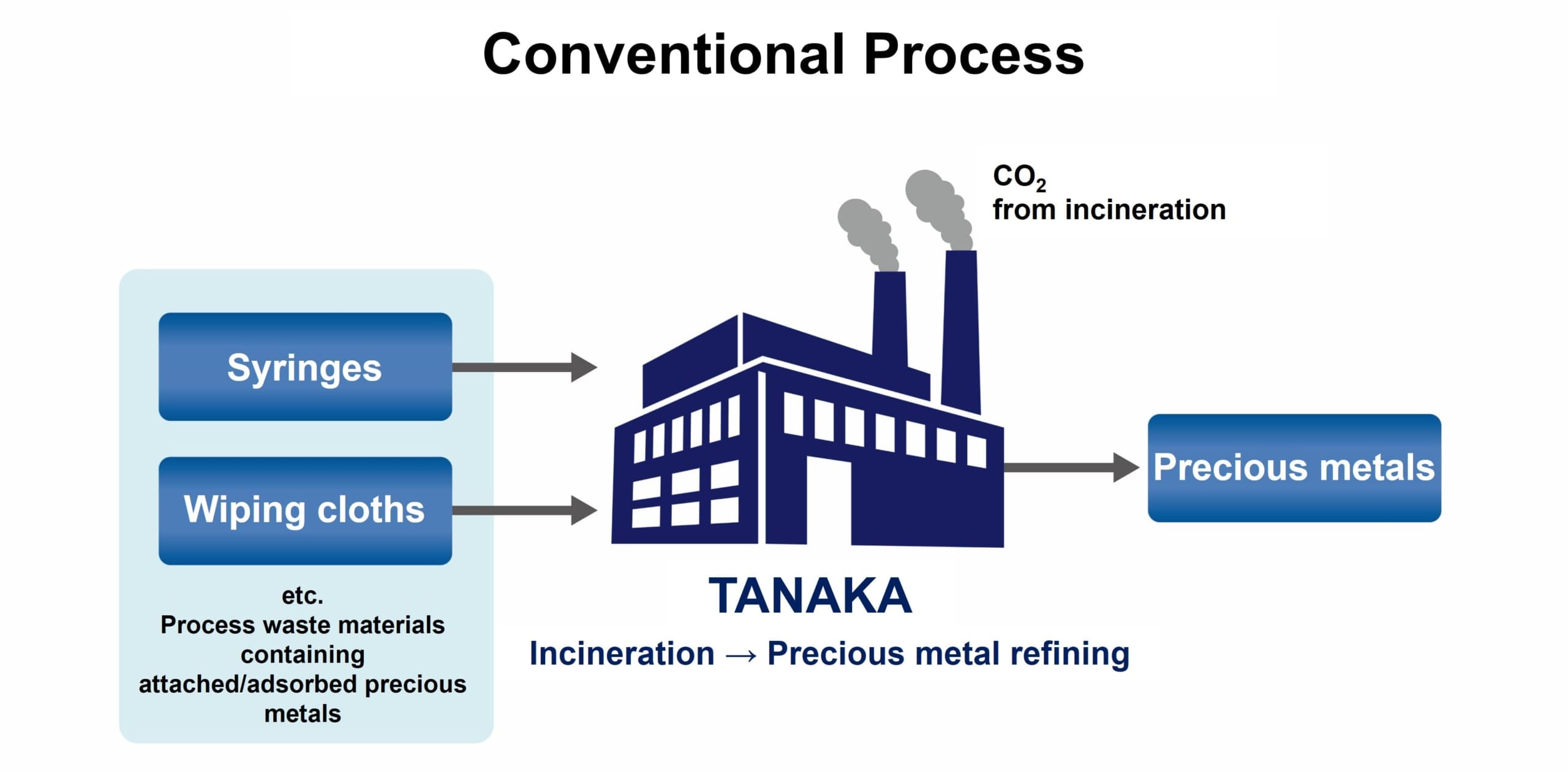

Since its founding in 1885, TANAKA has been a leader in the precious metals industry, actively engaged in recycling these limited and valuable resources. Among the process waste materials received from customers who request recycling, those containing organic materials (plastics) as main components with precious metals attached or adsorbed have traditionally been processed through incineration to remove the organic materials, with precious metals then recovered from the ash left behind.

While this incineration process has addressed the removal of environmentally regulated substances, the reduction of CO2 generated during the combustion of organic materials has become a major challenge in realizing a decarbonized society.

■Transforming the Precious Metal Recovery Process Through a Business Partnership with JEPLAN

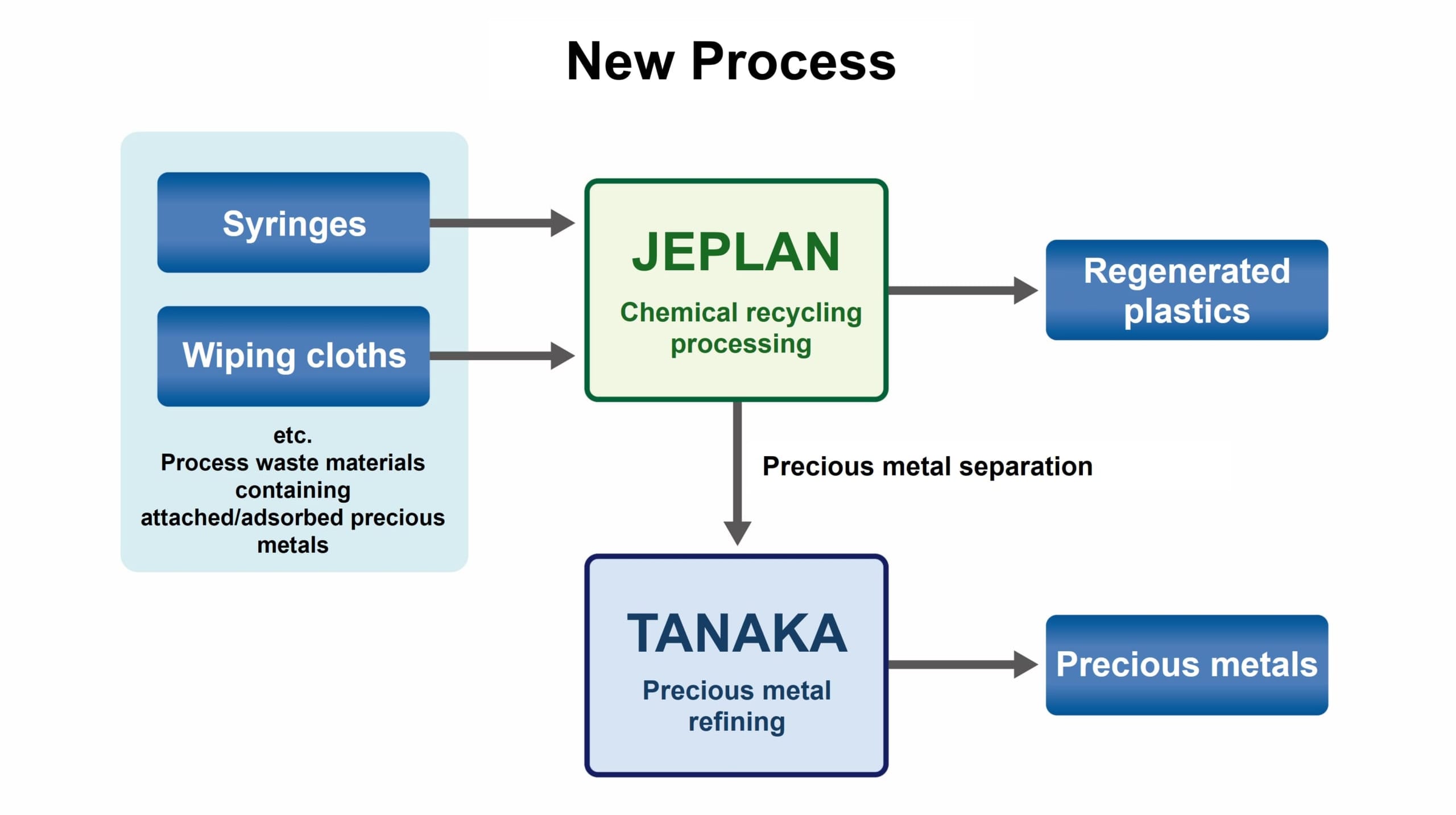

JEPLAN has established proprietary chemical recycling technology for polyethylene terephthalate, a type of plastic. To address the aforementioned CO₂ emissions issue, TANAKA is considering using chemical recycling in the future, in addition to the conventional precious metal recovery process through incineration. This initiative is being explored through a business partnership with JEPLAN. The materials targeted for chemical processing include plastics such as syringes and wiping cloths. CO2 emissions from the targeted precious metal recovery process are expected to be reduced to approximately 10% of conventional levels.

In addition, this process enables not only precious metal recovery, but also plastic regeneration, with TANAKA and JEPLAN each contributing to the realization of a decarbonized, circular society through their respective areas of expertise.

【JEPLAN, INC.】(https://www.jeplan.co.jp/en/)

Representative: Masaki Takao, Representative Director, President, and Chief Executive Officer

Established: January 2007

Main Business: Business based and related to PET chemical recycling technology (for PET bottles, polyester), etc.

The JEPLAN Group aims to realize a circular economy with its mission of “We circulate our world.” We use our proprietary PET chemical recycling technology to break down waste PET (PET bottles, polyester fibers, etc.) into molecules and remove impurities, regenerating it into recycled materials of the same quality as petroleum-derived materials. Through our recycling efforts using this proprietary technology, we are realizing the recycling of limited resources and contributing to the reduction of CO2 emissions.

The JEPLAN Group operates PET chemical recycling plants at two locations, PET REFINE TECHNOLOGY CO., LTD. (Kawasaki City, Kanagawa Prefecture, for PET bottles) and Kitakyushu Hibikinada Plant (Kitakyushu City, Fukuoka Prefecture, for polyester fibers), and is also promoting technology licensing in Japan and overseas.