SHOW ROOM 01

TANAKA

DIGITAL SHOWROOM

SHOW ROOM 02

Tanaka Forum @ Plug and Play

SHOW ROOM 01

SHOW ROOM 02

Contents

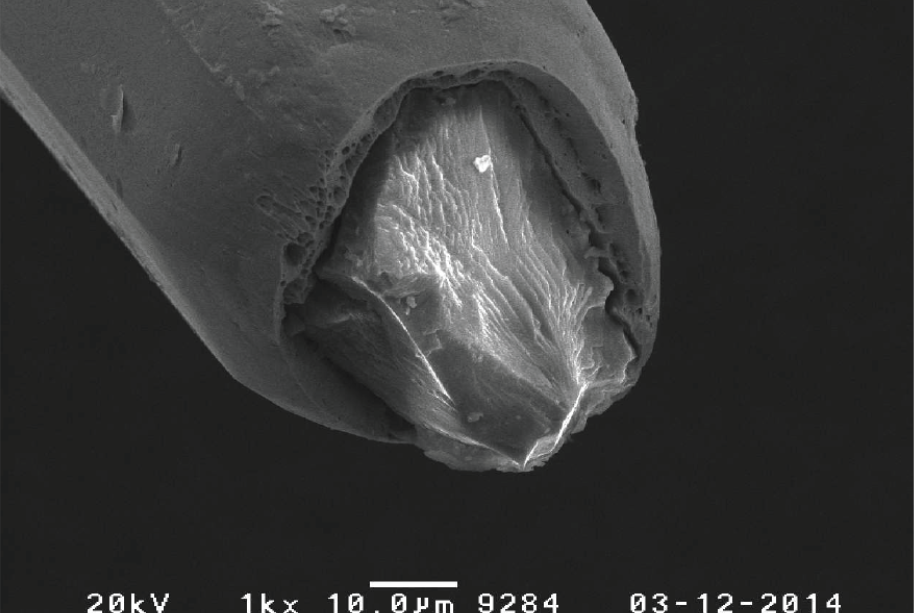

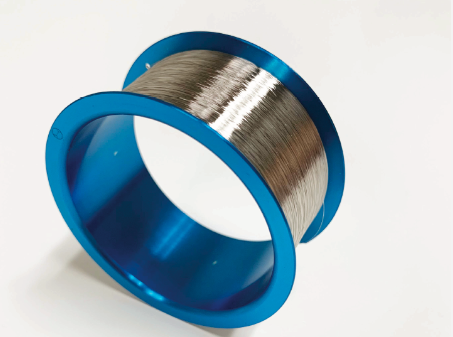

Our process significantly reduces inclusions of raw material and the melting process. It applies not only wire forming but also ring/tubing, sheet, and micromachining components.

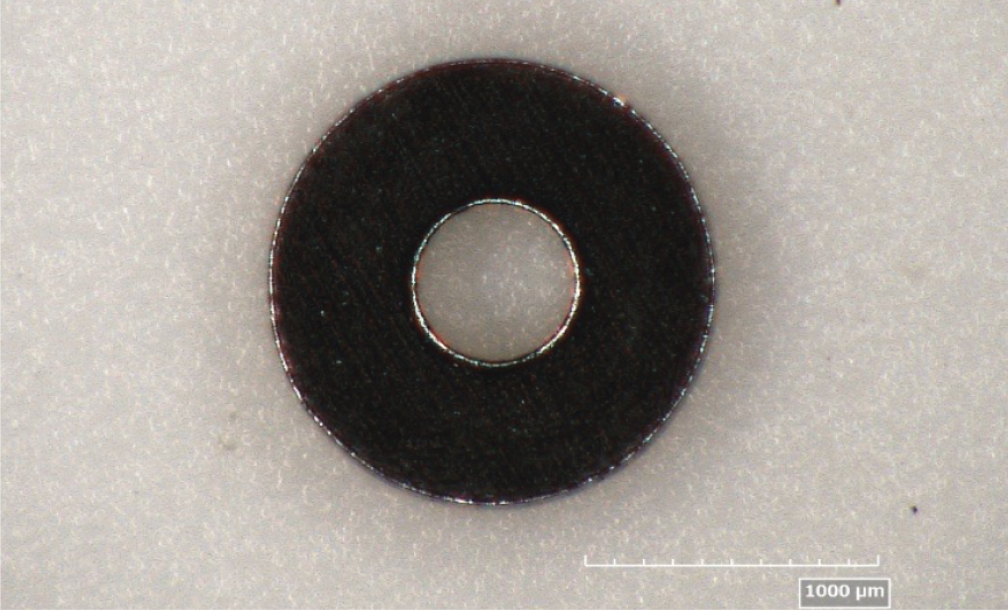

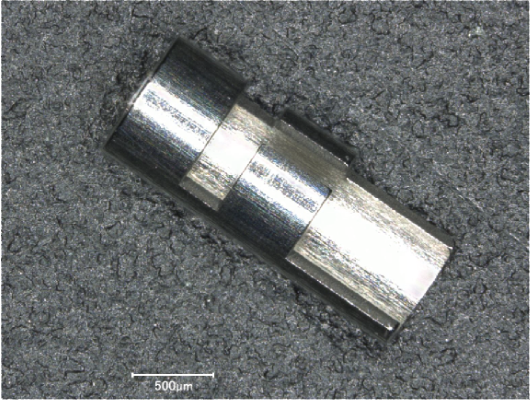

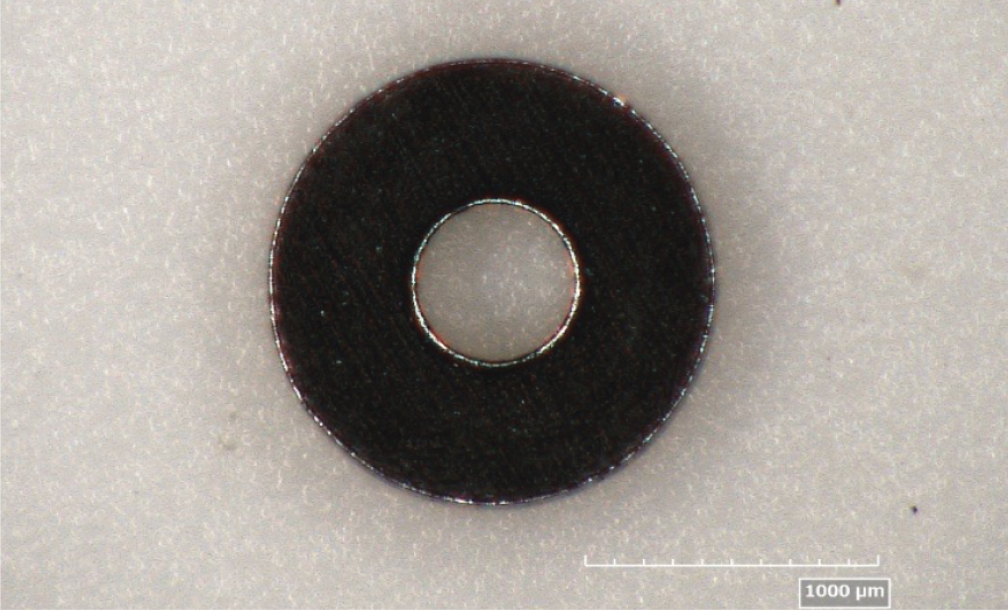

・Stent Graft, Stent

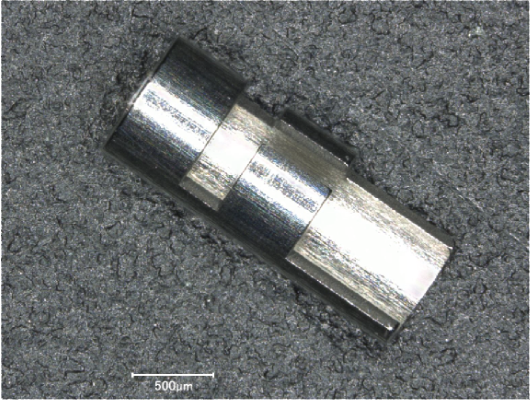

・Marker Band

For molding details, process design is required depending on the shape, material plate thickness, and product tolerance.

Laser machining of precious metal components for medical devices such as ablation catheter, irrigation catheter and IVUS catheter is available.

With the special laser, machining with good control of burr is made possible.

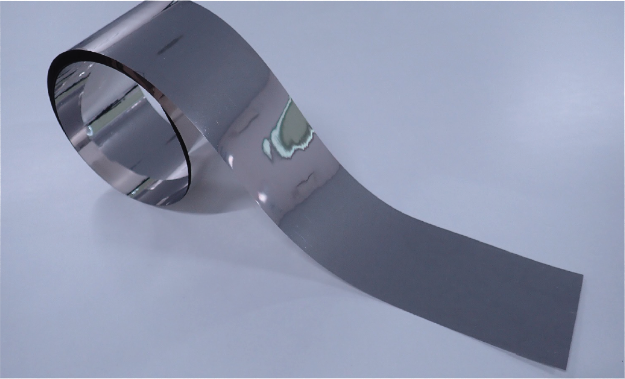

TANAKA provides Rh sheet with high quality characteristics which are important for mammography filter application: smooth surface, crackles, and good thickness control.

Standard thickness is 0.05mm.

TANAKA has developed a coating technology for wires that could save 12% of cost than non-coated one.

・Suppression of anomalous shape of wire

・Reduction of manufacturing defect caused by Die wear

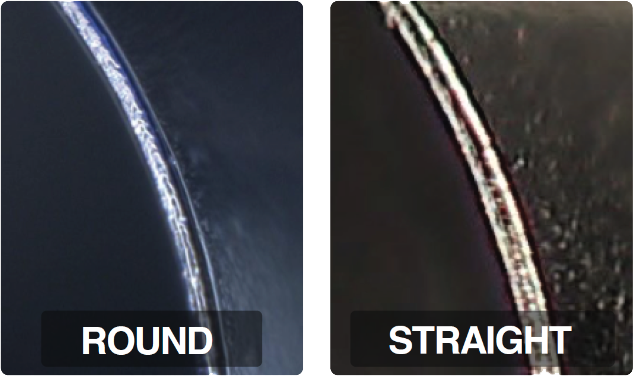

EDGING PROCESS: You can make a either choice of edging process from straight or round.

SURFACE PROCESSING: There is a variation for surface processing. You can customize to your preference.

Contents

TANAKA DIGITAL SHOWROOM

Details

Our process significantly reduces inclusions of raw material and the melting process. It applies not only wire forming but also ring/tubing, sheet, and micromachining components.

Details

・Stent Graft, Stent

・Marker Band

For molding details, process design is required depending on the shape, material plate thickness, and product tolerance.

Details

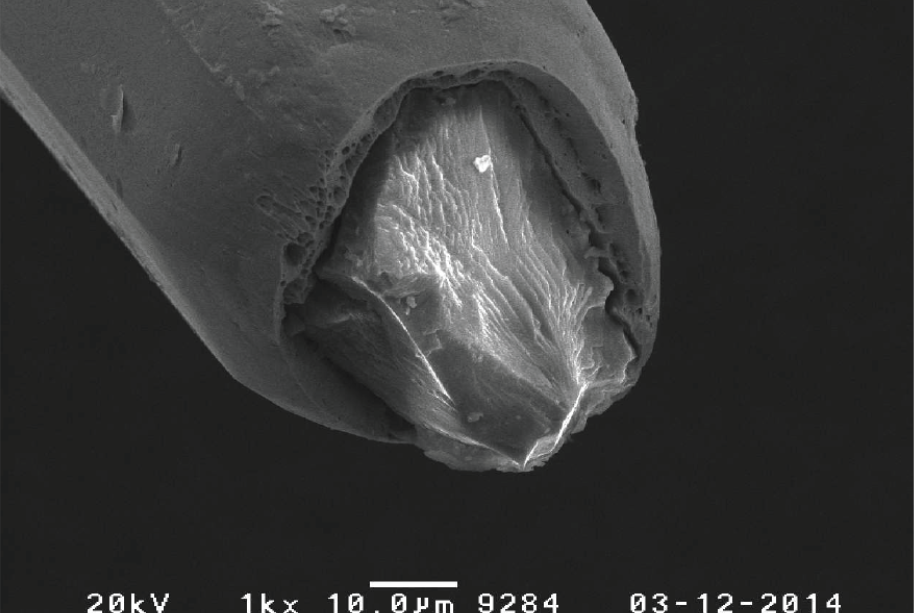

Laser machining of precious metal components for medical devices such as ablation catheter, irrigation catheter and IVUS catheter is available.

With the special laser, machining with good control of burr is made possible.

Details

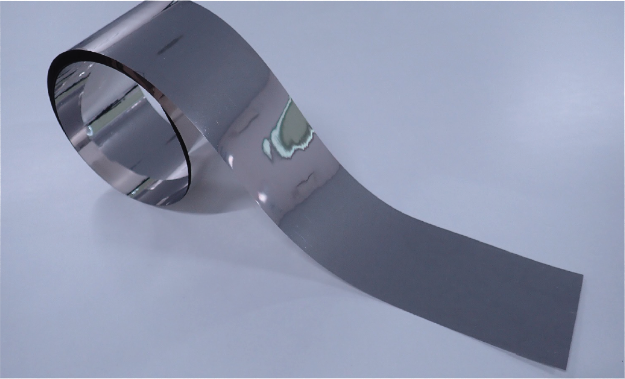

TANAKA provides Rh sheet with high quality characteristics which are important for mammography filter application: smooth surface, crackles, and good thickness control.

Standard thickness is 0.05mm.

Details

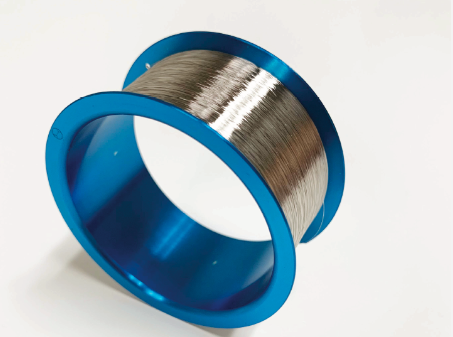

TANAKA has developed a coating technology for wires that could save 12% of cost than non-coated one.

・Suppression of anomalous shape of wire

・Reduction of manufacturing defect caused by Die wear

Details

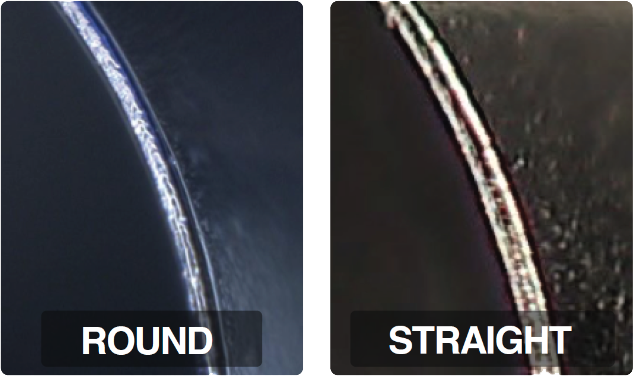

EDGING PROCESS: You can make a either choice of edging process from straight or round.

SURFACE PROCESSING: There is a variation for surface processing. You can customize to your preference.

Details

Please input your customer information

TANAKA DIGITAL SHOWROOM