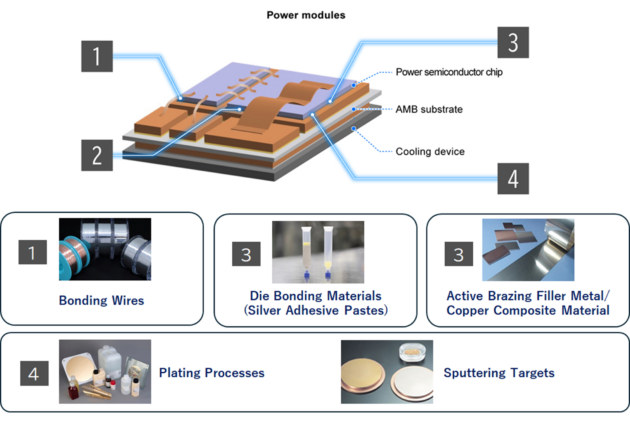

Precious Metals in Power Modules

Precious metal materials used in power devices require three main functions to support highly reliable and high-performance operation.

【Three functional classifications of precious metal materials in power devices】

| # | Classification | Function Name | Description | Typical Precious Metals |

|---|---|---|---|---|

| 1 | Electrical function | Improvement of conductivity and contactability | Flow a stable current with low resistance Ensuring electrical connectivity such as wire bonding |

Au, Ag, Pd |

| 2 | Thermal function | Heat dissipation and junction heat conduction | Efficiently dissipate heat from the device Thermal resistance reduction by backside junction (sintering) |

Ag, Au |

| 3 | Chemical and interfacial stabilization | Antioxidation, diffusion, and interface stabilization | Antioxidation at high temperatures Prevents metal diffusion with Cu and Al Ensuring interface reliability |

Pt, Pd, Au |

Role images for each function

✅ Electrical functions (electrodes and wiring)

- Au and Ag: Very high conductivity and low contact resistance

- Pd: Difficult to oxidize and high contact stability with Ni and Cu

✅ Thermal functions (heat dissipation and bonding)

- Ag: One of the highest thermal conductivity among metals (≈ 400 W/mK)

- Sintered Ag: Mainstream as a backside bonding material for SiC and IGBT

- AuSn solder: Eutectic bonding material with excellent high-temperature reliability

✅ Chemical and interfacial stability (barrier and stability)

- Pt/Pd: Hardly oxidizable at high temperatures, ideal for diffusion barriers with other metals

- Au: Hardly oxidizable, high chemical stability at metal interfaces