CLOSE

About Elements

TANAKA is a leading company in the field of precious metals.

Advanced materials and solutions that support societal progress, the development stories behind them, the voices of engineers, and our management philosophy and vision—

Elements is an online media platform that shares insights that lead to a better society and a more prosperous future for the planet under the slogan “Mastering Precious Metals.”

Scientists accidentally capture metals ‘healing’ themselves

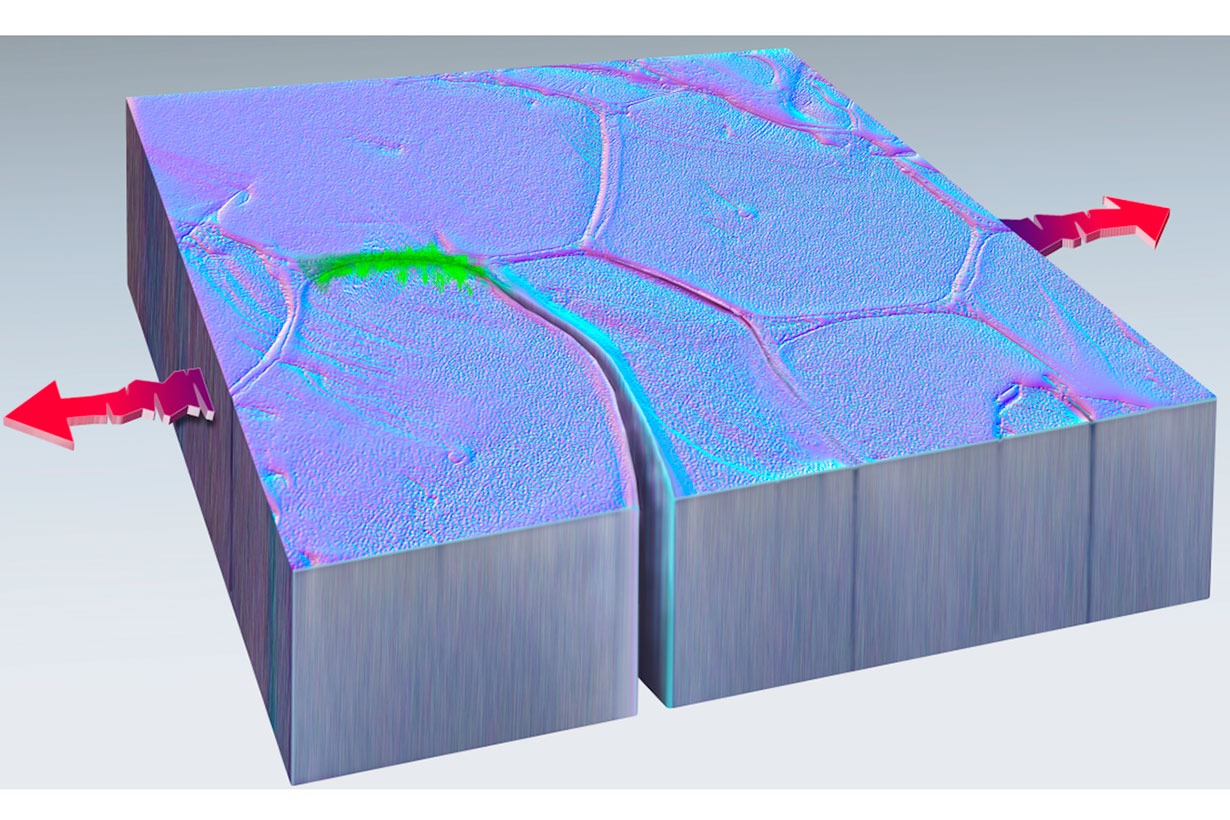

Contrary to previous beliefs, metals like copper and platinum can actually repair themselves. Top Image Credit: Dan Thompson / Sandia National Labs

Metals aren’t known to “heal” themselves on their own; once they break, it’s assumed the materials remain broken unless outside forces reform them. But new research into metallic properties indicates this isn’t always the case. In fact, some metals appear to naturally mend of their own accord—a discovery that could one day change engineering designs here on Earth and beyond.

According to a study published last week in Nature, materials scientists from Sandia National Laboratories in Albuquerque, New Mexico, and Texas A&M University discovered at least some metals—in this case copper and platinum—can “undergo intrinsic self-healing.” As Live Science recently noted, the team’s observations came completely by accident while observing the two materials at a nanoscale level.

[Related: Watch this metallic material move like the T-1000 from ‘Terminator 2’]

The discovery occurred while testing the stress resiliency properties of extremely tiny samples of platinum and copper. To do this, the team subjected the metals to rapid, miniscule prodding via a transmission electron microscope at a rate of 200 taps per second. Although the device only applied pressure akin to that of a mosquito’s legs walking, the metals still developed small cracks over time.

Such issues occur everyday in the real world. “From solder joints in our electronic devices to our vehicle’s engines to the bridges that we drive over, these structures often fail unpredictably due to cyclic loading that leads to crack initiation and eventual fracture,” Brad Boyce, a materials scientist at Sandia National Labs, said in a recent press release. “When they do fail, we have to contend with replacement costs, lost time and, in some cases, even injuries or loss of life.”

Within 40 minutes of the team’s testing, however, both the platinum and copper samples healed as if the fissures were never even there.

“Cracks in metals were only ever expected to get bigger, not smaller. Even some of the basic equations we use to describe crack growth preclude the possibility of such healing processes,” Boyce in the press release.

[Related: This giant solar power station could beam energy to lunar bases.]

While a surprise for many of the researchers, the healing abilities actually confirmed a decade-old theory first put forth by Michael Demkowicz, a materials sciences and engineering professor then at MIT. In 2013, Demkowicz attempted to correct conventional materials theory via computer simulations showing that, under certain conditions, metal hypothetically could mend stress-induced cracks. The key to such a startling ability comes via what’s known as “cold welding,” in which the flanks of two cracks are pressed into one another under very certain conditions.

Much still remains to be explored and tested, but such implications could be far-reaching, altering how engineers design and build everything from buildings on Earth to space faring vehicles. The recent experiments were conducted in a vacuum, but the team hopes to learn if metal cold welding could occur in normal atmospheric conditions. If nothing else, Demkowicz thinks the discovery is an excellent reminder that, “under the right circumstances, materials can do things we never expected.”

This article was written by Andrew Paul from Popular Science and was legally licensed through the DiveMarketplace by Industry Dive. Please direct all licensing questions to legal@industrydive.com.

![]()