NEWS/RELEASE

TANAKA PRECIOUS METAL TECHNOLOGIES Develops AgSn TLP Sheet, a Sheet-type Bonding Material for Power Semiconductors

Compatible with large chip sizes of 20mm, enabling highly reliable bonding over extensive areas and contributes to growing demand for high-current power semiconductors in electric vehicles, hybrid automobiles, industrial infrastructure, etc.

January 23, 2025

TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd. , which engages in the industrial precious metals business of TANAKA, has announced the development of the AgSn TLP sheet, a sheet-type bonding material designed for die attachment in the manufacturing of power semiconductor packages. Additionally, the AgSn TLP sheet is anticipated to serve as an alternative to thermal interface materials*1 (TIMs) for large-area bonding in heat sinks, further expanding its potential applications.

■ Sheet Bonding Material That Allows Bonding of High-Current Large Silicon (Si) Chips

In recent years, there has been rising demand for high-current power semiconductors centered on applications such as electric vehicles, hybrid vehicles, and industrial infrastructure. As such, in the bonding of large Si chips, there are requirements for materials that can allow the bonding of large areas while guaranteeing high reliability. The AgSn TLP sheet announcement declares that it can be used for semiconductor chip bonding of up to 20 mm. Furthermore, it allows bonding at a low pressure of 3.3 MPa, contributing to the improvement of yield in semiconductor manufacturing.

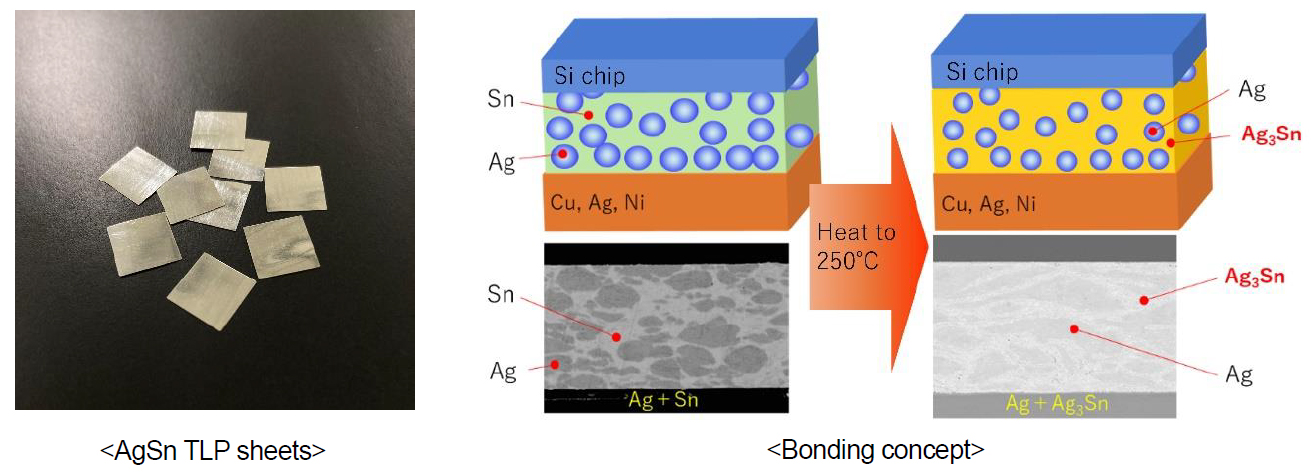

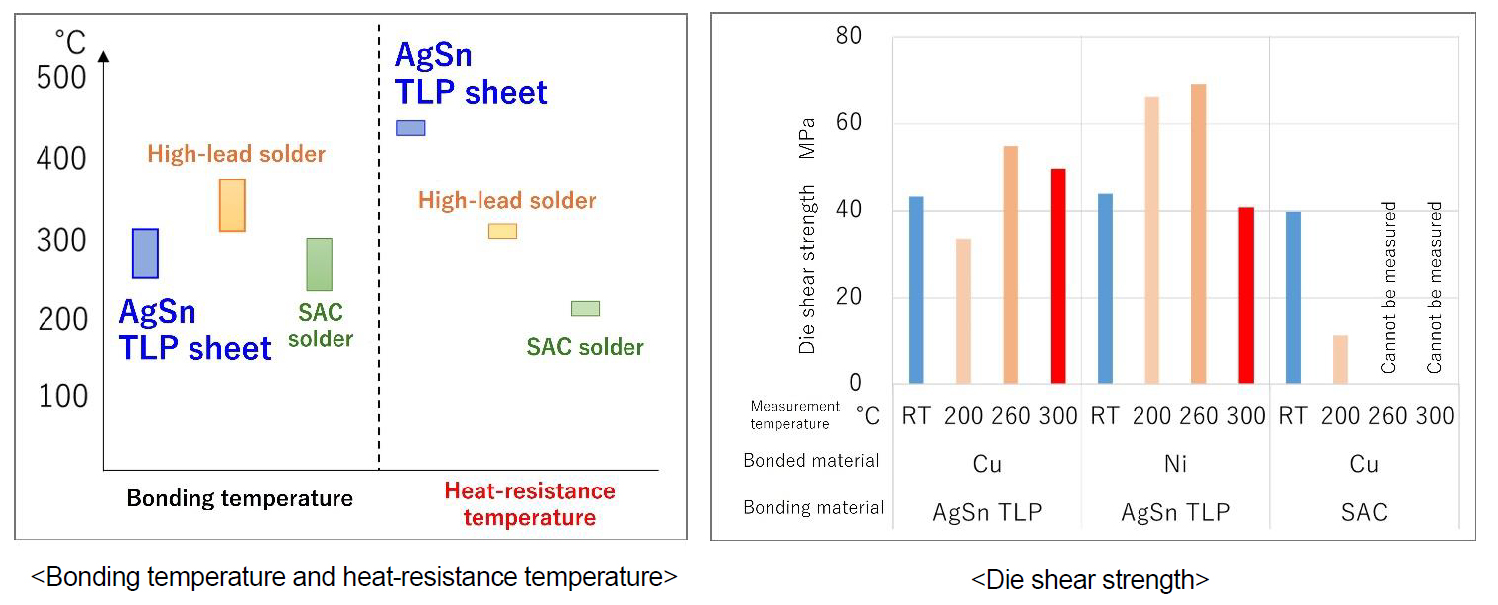

■ Low-Temperature Bonding and High Heat Resistance Required for Power Semiconductors to Contribute to Heat Management

Semiconductor devices—including power semiconductors—require high heat resistance as high temperatures may cause failures or shorten lifespans. In addition, the primary bonding materials currently adopted in the manufacturing of power semiconductor packages generally include high-lead solder which is being replaced with other materials due to its impact on the environment*2, SAC solder*3 which has low heat resistance, and silver (Ag) sintering agents. The heating temperature of this product is 250℃, allowing transient liquid phase diffusion bonding*4. As the heat-resistance temperature rises to 480℃ after bonding, it has higher heat resistance than existing products. It can also be used with various types of bonded materials, as it can maintain a bonding strength of up to 50 MPa. Furthermore, this product is a lead-free bonding material, and it also features high bonding reliability that has passed heat cycle testing of 3,000 cycles.

As large-area bonding is possible, besides application as a die attachment material for power semiconductors, it is also expected to be used as an alternative to TIMs. Various materials with high thermal conductivity have been developed for semiconductor package manufacturing, but the low thermal conductivity of TIM materials has been a bottleneck in total thermal design. This product is a bonding material that allows large-area bonding of TIMs above 50 mm and has high thermal conductivity. It can be expected to contribute toward heat management in the manufacturing of semiconductor packages.

________________________________________________________________________________

*1 A thermal interface material (TIM) is a heat conducting material inserted between materials to dissipate unwanted heat generated in electronic devices.

*2 Although lead is under the scope of regulation by the RoHS Directive, use under a validity period is allowed for applications for which substitutes are not possible scientifically or technically. However, the development of substitutes is underway due to exclusion under the validity period.

*3 SAC solder is a solder material that contains tin (Sn), silver (Ag), and copper (Cu).

*4 Transient liquid phase diffusion bonding, also known as TLP bonding, is a bonding method that temporarily melts and liquifies metals and such inserted in the bonding surface, then uses diffusion to bond through isothermal solidification when carrying out diffusion bonding.