CLOSE

About Elements

TANAKA is a leading company in the field of precious metals.

Advanced materials and solutions that support societal progress, the development stories behind them, the voices of engineers, and our management philosophy and vision—

Elements is an online media platform that shares insights that lead to a better society and a more prosperous future for the planet under the slogan “Mastering Precious Metals.”

TANAKA’s Hybrid Silver Adhesive Paste Redefines Reliability for SiC/GaN Power Modules

Source: Semiconductor Digest

Date: December 12 , 2025

Link: https://www.semiconductor-digest.com/tanakas-hybrid-silver-adhesive-paste-redefines-reliability-for-sic-gan-power-modules/

Senior Manager, Silver Adhesive Global R&D, TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd. Shintaroh Abe explains the materials breakthrough enabling high-temperature, pressure-less die attach.

As wide bandgap (WBG) semiconductors accelerate into mainstream power electronics, packaging reliability has become one of the most critical limiting factors. For SiC MOSFETs and GaN HEMTs operating above 200°C, the die-attach layer faces extreme thermal, mechanical, and chemical stresses — conditions far beyond what traditional solder or epoxy adhesives can handle.

TANAKA has responded with a hybrid silver adhesive paste engineered to deliver high thermal conductivity, strong bonding above 200°C, pressure-less processing, and long-term fatigue resistance.

-

The innovation, according to Shintaroh Abe, Senior R&D Manager at TANAKA, stems from solving two challenges at once: enabling silver to sinter inside a resin environment, and controlling resin distribution within the sintered network. “We made silver fillers sinter within resin—something normally impossible,” Abe said.

Abe explains that the first major breakthrough was allowing silver particles to sinter in the presence of resin, which ordinarily prevents sintering: “Sintering within resin is typically difficult because the resin blocks the sintering process,” Abe says. “By carefully controlling the resin’s thermal behavior and its interaction with the silver particle, we made it possible for the silver fillers to sinter within the resin during processing.”

-

The second breakthrough involved engineering the microstructure: “We succeeded in controlling the distribution of the resin within the sintered silver structure,” Abe said. “Instead of being uniformly dispersed, the resin is selectively located as a matrix within the silver sintering network.”

By positioning resin only where it is required, TANAKA created a composite system that maintains high thermal conductivity while dramatically lowering elastic modulus. “These two innovations achieved at the same time allowed us to maintain high thermal conductivity and add mechanical flexibility for long-term reliability. Conventional resin-based adhesives lose much of their bonding strength at temperatures above 200°C– so we had to combine adhesion with sintering,” Abe explained.

High-temperature reliability is a defining challenge for wide bandgap power modules. Traditional silver adhesives rely heavily on hydrogen bonding, which collapses at elevated temperatures. Abe explains the failure mechanism: “At higher temperature—more than 200 degrees Centigrade— adhesive systems that rely on hydrogen bonds do not work well. That means lower shear strength.”

To solve this, TANAKA blended sintered silver technology with its silver adhesion chemistry. “We combined the sintering technology with the adhesion technology. This enables good bonding strength even at more than 200ºC, while the resin disperses the stress during thermal cycling.”

The resulting material forms a stable structure that reduces thermomechanical fatigue, especially in copper- and ceramic-based power substrates.

Voiding control

Voids degrade both conductivity and reliability, especially in high-power modules. Abe describes their strategy: “We first increase the packing density of the silver filler. Many different sizes and shapes of silver particles are packed to be higher density.” After sintering, the resin melts and penetrates to the micro-void space, resulting in a denser and more stable structure,” Abe said. This reduces oxygen and moisture ingress. “Minimizing voids prevents the ingress of oxygen and moisture, which can lead to long-term degradation,” noted Abe.

Pressure-less Sintering

A key advantage is compatibility with standard die-attach workflows. “Pressure-assisted sintering requires specialized equipment. Our hybrid sintering supports pressure-less processing using existing heating systems like batch ovens,” Abe said. “This makes it easier for customers to adapt the material without major changes to their production lines.”

The same paste can still be used in pressure-assisted systems for customers who want to maximize density.

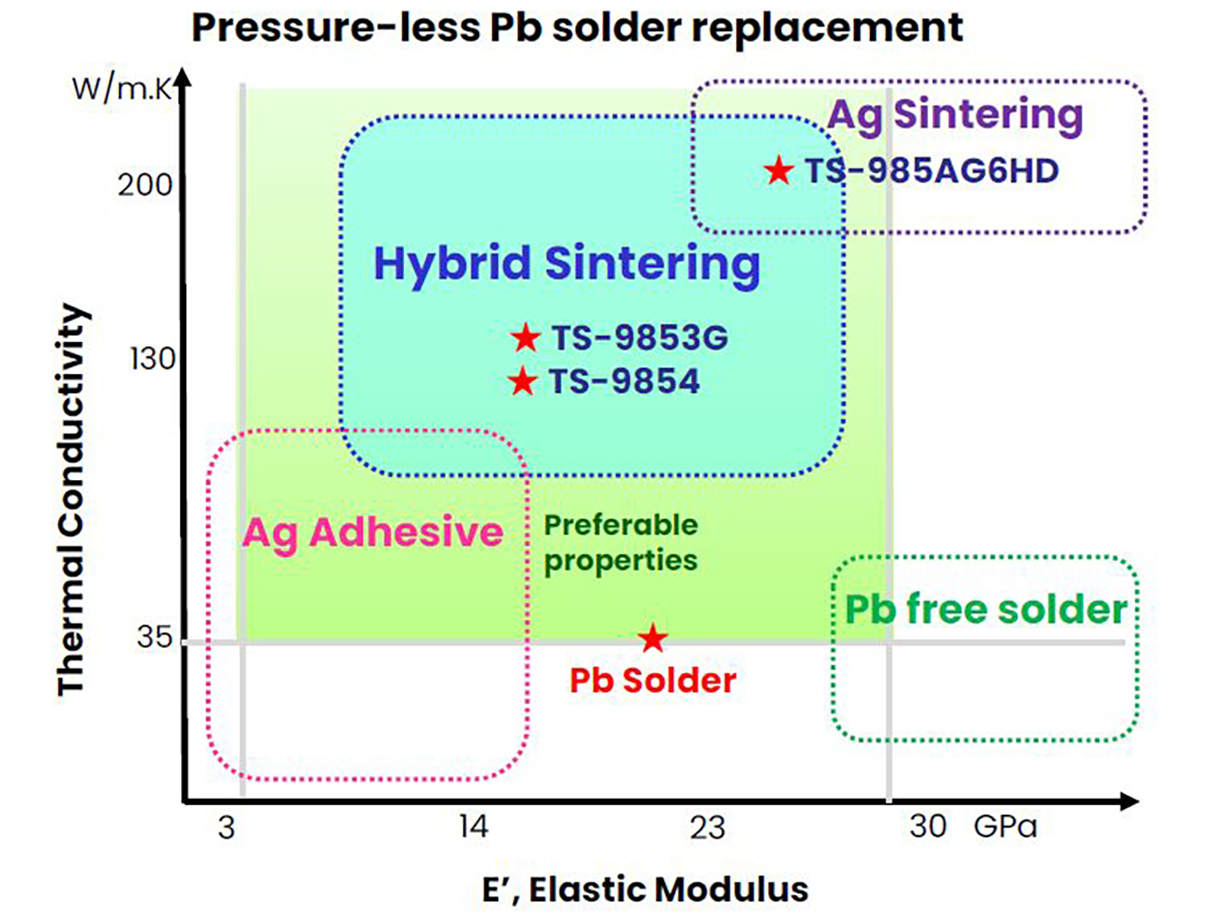

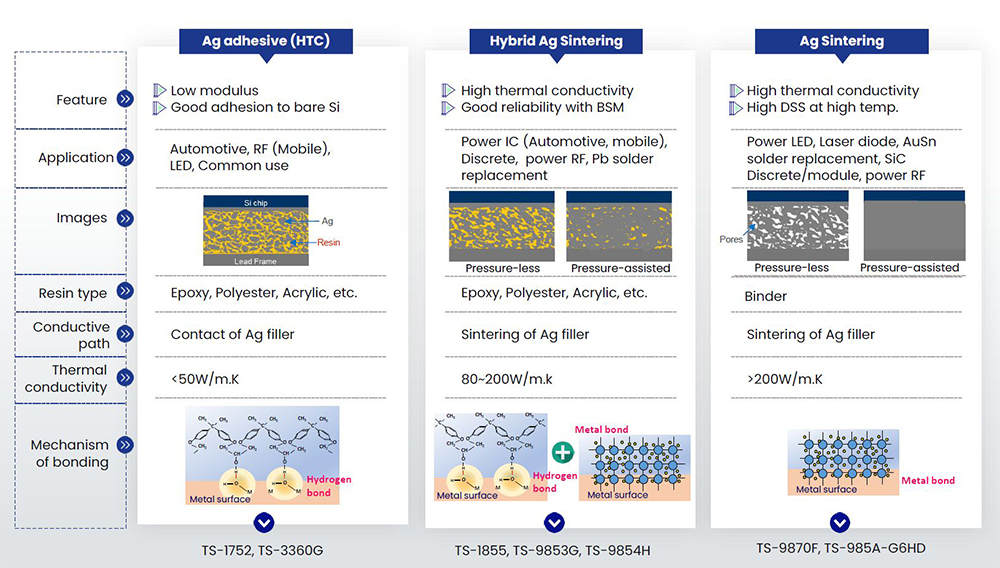

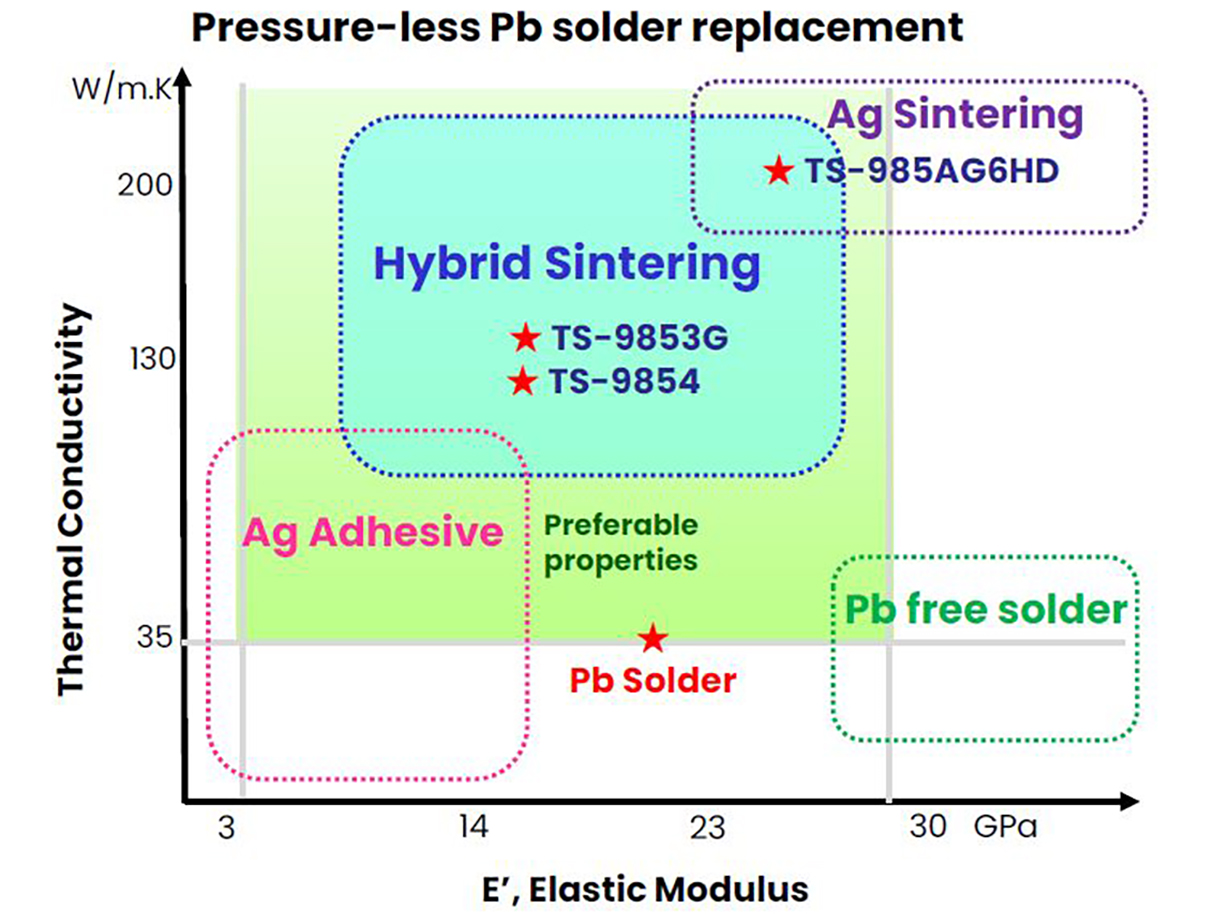

Figure 1 illustrates the TANAKA silver die attach product line, with the new hybrid sintering process in the center. Figure 2 shows how the hybrid sintering process compares with alternative processes and materials.

Figure 1

Figure 2

Substrate compatibility

Bare copper is among the most challenging surfaces to bond due to its thin and reactive oxide layer. “The most difficult to bond is bare copper, so we focused on that,” Abe said. “Our process has strong compatibility with bare copper. It’s also compatible with silver or gold metallized surfaces.”

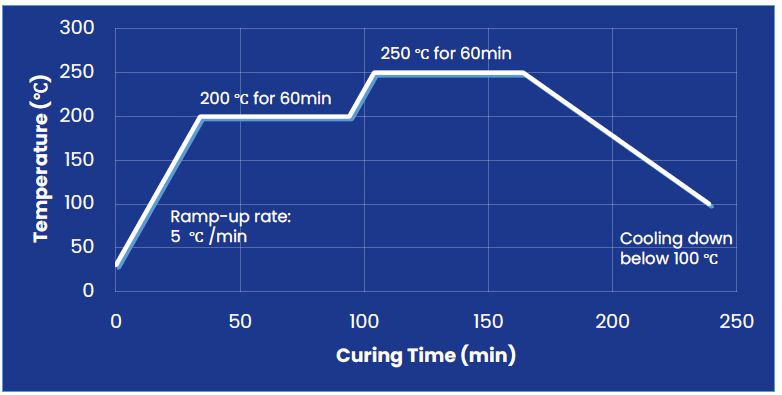

Hybrid pastes require precise control of silver particle dispersion and resin-silver interaction. Abe notes: “The performance of the material is highly sensitive to how the components are mixed and the order of the processing.” Figure 3 shows the recommended curing profile optimized for bare Cu, which is also suitable for Ag and Au surfaces. For Ag and Au, reliable bonding can be achieved at lower temperatures, around 200°C.

Figure 3

Fortunately, TANAKA’s industrial facility already has the infrastructure: “Our production facility has extensive experience producing various paste materials. This allowed us to transition smoothly from prototyping to mass production without major equipment investment.”

Beyond technical performance, TANAKA integrates a circular material supply chain. The company has developed environment-friendly and sustainable practices to reduce environmental impact and achieve sustainable and efficient use of precious metals by focusing on recovering and refining precious metals from industrial scraps. In addition to environmental benefits, circular sourcing also plays a strategic role in securing stable access to precious materials. For materials with limited production volumes that require robust procurement capabilities, recycling helps reinforce supply security—while also helping to reduce carbon emissions and support more sustainable production. The key feature of this approach is that products are composed of materials refined from recycled precious metals enhanced using advanced recycling technologies and precious metal analysis technologies developed by the Group over many years. Additionally, upon customer’s request we have the capability to provide products and solutions made of 100% recycled precious metals to support sustainability. “The circular economy and sustainable material supply are very important for our customers. Our recycling system and procurement ability are a key advantage,” Abe said. The hybrid paste is fully lead-free and PFAS-free.

Moreover, TANAKA provides a “One Stop Service” for everything about precious metals, from bullion supply to process and manufacture, sales and recycling.

Future directions

As packaging evolves toward thinner dies and more advanced multi-layer structures, TANAKA is preparing the next generation of adhesives. Abe outlines the roadmap: “Some customers are targeting below 50-micrometer die thickness. The paste material will face critical challenges to overcome overflow or die surface contamination.”

To address that, TANAKA is working on optimizing silver content while maintaining thermal and mechanical properties. “We are collaborating with customers and with European institutes for next-generation packaging.”

Cost reduction—both in material and processing—is also a key theme: “Next-generation demand is very complicated, so we must follow the trend carefully and also reduce cost from both the material and process sides,” Abe said.

TANAKA’s hybrid silver adhesive paste is more than a new bonding material—it represents a shift in how the industry approaches the longstanding tradeoff between thermal performance and mechanical resilience. By enabling sintering within a resin framework, optimizing particle packing, and supporting pressure-less processing, the material aligns directly with the needs of SiC/GaN power modules entering high-volume markets.

As Abe puts it: “Our hybrid sintering adhesive is well-aligned with the requirements of next-generation power electronics, where long-term reliability and thermal efficiency are critical. We remain committed to contributing to semiconductor innovation by applying the extensive materials expertise we have developed over decades.”

Related Information