TANAKA’s Initiatives for Power Devices

Reliability and Innovation

TANAKA—which has continued to provide innovative solutions for the semiconductor, electronic device, automotive, and energy industries, handling industrial precious metal materials for over 100 years—provides total solutions that are unique to the Group.

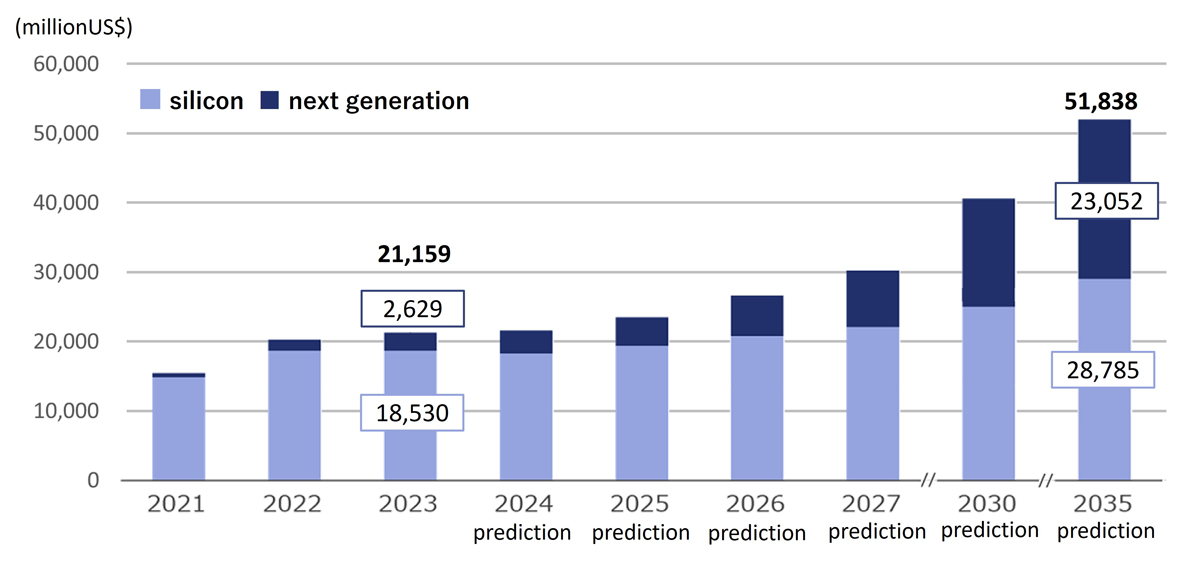

Expanding Power Device Market and Expectations on Development of New Materials

Global Market for Power Semiconductors

Source: Fuji Keizai “2024 Edition Current Status and Future Prospects of Next-Generation Power Devices and Power Electronics Related Equipment Market” (Processed by our company based on Fuji Keizai data, converted at 150 yen per US$.)

Power devices withstand high voltages and control high currents. They are found in vehicles and are particularly indispensable for electric vehicles. This is also a technology that is essential for infrastructure in terms of industrial machinery, railway, and heavy electrical equipment. In addition, they also receive attention from the perspective of energy saving as they efficiently manage energy and help reduce energy consumption. As key devices essential for achieving energy savings, they are used in a wide range of fields, with growing demand in these fields which include digital terminal devices such as personal computers and smartphones, home appliances such as television and air-conditioners, and even artificial satellites and base stations for next-generation communications. Together with the growing market needs, the development of new technologies is also accelerating, and power devices are required to achieve higher output and efficiency. For components, besides high thermal cooling, heat resistance, and bonding reliability, it has become necessary to develop new materials that can respond to further miniaturization.

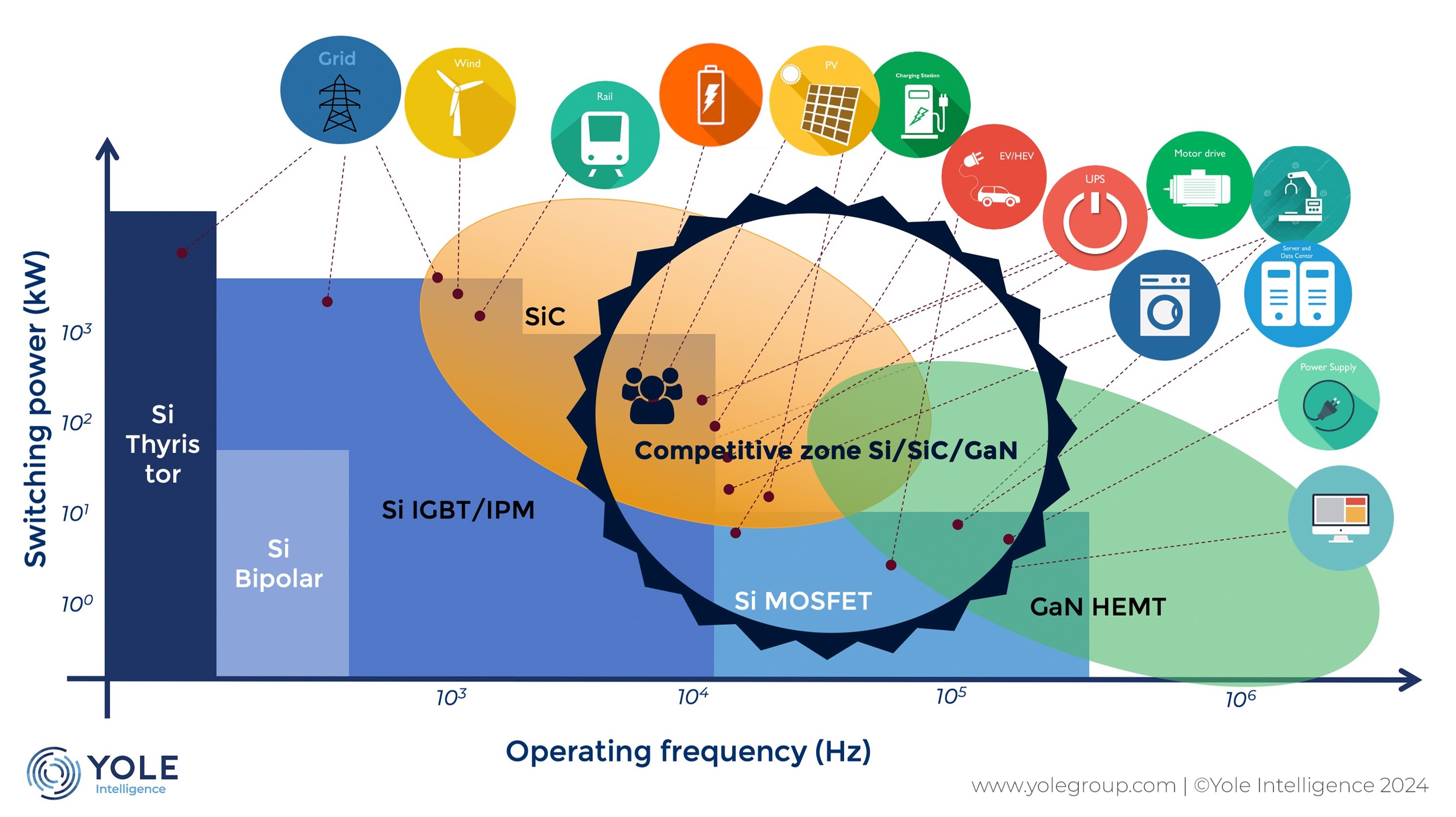

Expanding Power Device Market and Technological Trends

Source: Status of the Power Electronics Industry report, Yole Intelligence, 2023

Besides the improvement of technologies based on Si, which has been the mainstream, power devices are in a transition period for the mass-production development of next-generation devices represented by SiC and GaN. To achieve further miniaturization and power performance at the same time, there will be greater demand for materials to have “low resistance” and “thermal cooling measures”.

Contributing to Power Devices Through Materials with

“Low Resistance” and “Thermal Cooling Measures”

TANAKA’s Products for Power Devices, Offering Total Solutions

Bonding Wires

Al Wire/Ribbon

- Good bondability

- Good moisture resistance

Cu Wire/Ribbon

- Low electrical resistance

- High fusing current

Die Bonding Materials

(Silver Adhesive Pastes)

Ag-Adhesive

- Good adhesion to bare Si

Hybrid Ag-Adhesive

- High thermal conductivity

- Good reliability

Pure sinter-Ag

- High thermal conductivity

- High Hot-DSS

Active Brazing Filler Metall/Copper Composite Material

Thick Cu circuit formation

- Etching-less method

- Possible to thinner brazing metal layer

Binderless

- Easy maintenance of the furnace

Shorter heat processing time

- Lower brazing temperature

Various Types of Electrodes and Metalized Layers

Plating Processes

Metalized Layers for Bonding Pads

- Ni/Pd/Au, Ni/Au, Ag, etc.

- Proposals appropriate for material combinations of bonding wires and pads

- Balance of high reliability and high productivity

Rear-side Electrodes for Ohmic Contacts

- Ni/Au, etc.

- Limit wafer warping through low stress

- Good die-attach bondability

For Lead Frames, Copper Clips, and PCBs

- Ni/Pd/Au, etc.

- Prevent spreading of Ni layer

- Make Au layer into a thin film and reduce overall costs

Sputtering Targets

Various Types of Precious Metal and Alloy Targets

- Pure precious metal targets such as Au, Ag, Pt, Pd, and Ir

- Precious metal alloy targets

- High-purity targets suitable for various types of electrodes and metalized layers

- Deposition that is free of pinholes, oxides and gases

- Silver alloy targets with high environmental resistance (sulfur resistance and humidity resistance)

In the field of power devices that requires further sophistication in the future, we develop and provide various products using processing technologies developed over many years that fully apply the potential of precious metal materials as well as elements that are not precious metals.

Contact us for more information.

Global Development System and Customer Service

We use our strengths from involvement in the semiconductor industry over many years to provide total solutions.

- We have development sites around the world and can carry out speedy development and customer response according to our customers’ needs.

- We have assembly and evaluation equipment similar to our customers’ to accelerate the speed of development.

- From multiple product lineup, we propose the optimal material combination that achieves both high reliability and high production efficiency.

- We have established a recycling system that turns substances containing precious metals—such as scraps generated during research and development and in the manufacturing process—back into pure precious metal bullion. We implement a research and development system that allows us to repeatedly take on challenges using precious materials.