CLOSE

About Elements

TANAKA is a leading company in the field of precious metals.

Advanced materials and solutions that support societal progress, the development stories behind them, the voices of engineers, and our management philosophy and vision—

Elements is an online media platform that shares insights that lead to a better society and a more prosperous future for the planet under the slogan “Mastering Precious Metals.”

Precious Metals: Powering a Sustainable Future for the Auto Industry

Precious metals are key components for the fast-growing automotive industry. They can enable advanced products such as electric vehicles, which can be regarded as a collection of electronic devices, and fuel-cell vehicles that use hydrogen as energy.

Global demand for precious metals will only increase as the auto industry continues to transition toward smarter, more fuel-efficient products. Consider that a hybrid vehicle has approximately 33,000 parts and counting,1 which includes many types of precious metals—platinum, gold, and silver—and other metals such as aluminum and copper are frequently used. Precious metals can be found in exhaust purification systems, LED display elements and sensing materials, to name a few.

However, high-demand materials are always vulnerable to supply chain disruptions. The COVID-19 pandemic presents new challenges for the auto industry, as evidenced by shortages of semiconductors and other key components. Competition for resources means the auto industry must carefully consider how it sources precious metals.

Technology suppliers that prioritize recycling and reuse of these materials provide many inherent advantages. This includes increased availability of resources and more sustainable practices that help instill consumer confidence and meet corporate social responsibility standards.

1 Tanaka website, https://tanaka-preciousmetals.com/en/elements/article21/

Precious metals: Moving the auto industry forward

Most of the world’s mined platinum group metals, including platinum, palladium and rhodium, are found in automotive applications.2 These precious metals have been in use for many years in drive systems for internal combustion engines. This includes platinum-iridium alloy wires for spark plugs, silver-platinum paste for injectors, and gold paste for rear-window defoggers. Many of these same elements are now having a significant impact in the advancement of next-generation vehicles, including:

Electric vehicles:

- LEDs for monitor/warning devices

- Seat sensors and air bags

- Brake attrition detection sensors

- Millimeter-wave radar

- Defoggers-rear windows

- Lever combination switches

- LED display elements

- Driver ICs for displays

Plug-in hybrid vehicles:

- Engine control units

- IGBT

- Hybrid integrated circuits for AC/DC converters

- Inverters

- CMOS in-vehicle cameras

Fuel cell vehicles:

- Fuel cell stacks

2 Business Insider, “Precious metals are crucial for the future of automotive manufacturing,” Feb. 6, 2019.

Coming full circle: Recycling fuels future growth

Like many materials, resources for precious metals are limited. Recycling is already becoming an essential function of the precious metals supply chain. Forward-thinking suppliers are extracting these elements from “urban mines”—the vast amount of electronics and other waste discarded every day by businesses and consumers. Some key stats to consider:

6,800

- tons of gold exists in “urban mines.”3

1 million recycled cellphones yield:

- 35,000 pounds of copper

- 772 pounds of silver

- 75 pounds of gold

- 33 pounds of palladium.4

3 National Institute for Materials Science, IAA, https://www.nims.go.jp/eng/news/press/2008/01/p200801110.html (2019.07.04)

4 Recycling Today, “Electronic scrap processors see profits, despite decline in precious metals,” June 27, 2021.

Precious metals: A catalyst for sustainable energy solutions

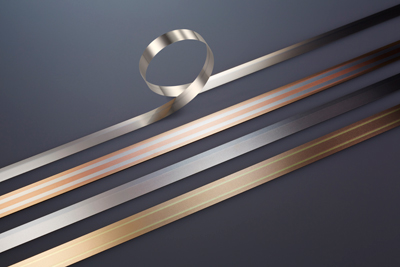

Precious metals are playing an increasingly important role in helping auto manufacturers meet emissions standards and sustainability goals. For example, bonding wire is a primary component in semiconductors and lithium-ion batteries.5 Bonding wire connects the electrodes of the battery’s cylindrical cells to the busbar.6

Additional technologies of note include:

Fuel cell catalysts:

Fuel cell electric vehicles (FCEV) are growing in popularity, especially in the commercial market. Several large automakers have announced plans to develop FCEVs in the coming years, including General Motors, Hyundai, Toyota and Honda.7 Fuel cell catalysts are made of precious metals and are essential components for facilitating reactions in fuel cells. Some of the latest advancements in fuel cell catalysts are resulting in lower costs and greater efficiencies. For example, Tanaka recently developed a platinum-cobalt alloy hydrogen electrode catalyst through industry, academia and government that reduces peroxide generation—which causes electrolyte degradation—by approximately 50%.

Exhaust gas purification catalysts:

These systems purify potentially harmful emissions by breaking them down into water and carbon dioxide. Precious metals, such as platinum and palladium, are applied to base materials to create a honeycomb structure. When potentially harmful emissions pass through these materials, they are purified through a chemical reaction.8

5 Business Insider, “How wire is a critical component in the automotive industry’s shift to electric vehicles,” Nov. 18, 2021

6 ibid

7 We are the Mighty, “Hydrogen fuel cells could be the future of the military (and everyone else),” Jan. 5, 2022.

8 Business Insider, “A Japanese precious metals company makes purification technology that can help reduce air pollution. Here’s how it works,” April 30, 2021.

Securing the supply chain for today and tomorrow

The recent semiconductor chip shortage reinforces the need to build strong supplier relationships and partner with technology providers who are developing solutions with price, availability and sustainability in mind. Tanaka Precious Metals will establish a supply chain network and material solutions that enable continuous innovation in the auto industry.

This includes comprehensive solutions that span the entire resource cycle from procurement to processing to recycling.

Diversified Solutions

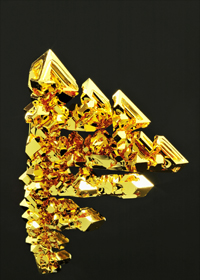

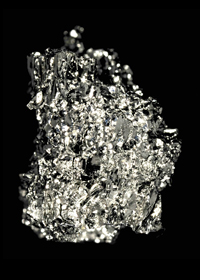

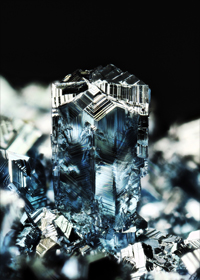

Tanaka has expertise and products based on eight precious metal elements, including:

- Platinum

- Gold

- Silver

- Palladium

- Rhodium

- Iridium

- Ruthenium

- Osmium

Metal sample imagery courtesy of Ryoji Tanaka.

Precious Metal Library

Tanaka has built a network of supply routes and international facilities to ensure ongoing material availability from nearly any location around the world. The company’s R&D expertise has been pivotal in bringing new technologies to market, including recent awards for the development of a hydrophobic precious metal catalyst as well as efforts around fuel-cell catalysts.

Recycling Expertise and Security

Tanaka continues to grow its recycling business. The company recovers materials from automobile catalysts and refines them into platinum and palladium. Tanaka offers the purified precious metals as compounds for use in sputtering targets, IC package test pins, and various thick-film paste/epoxies for use in new electronics. This level of recycling requires high technical expertise and trust. Tanaka is sensitive to the highly confidential nature of waste materials. The company understands that urban mines are a “mass of secrets” filled with highly valued intellectual property. Tanaka invests a considerable amount of money into security for recovered materials to ensure confidentiality.

In the coming years, recovering materials from urban mines will become more challenging with the development of alloy technology. However, Tanaka’s strength lies in the cooperation of each business division adopting recycling as a core strategy. Tanaka is one of only a few manufacturers in the world involved in both recovery/refining and material development. The company’s R&D department closely follows trends in alloy materials, so the introduction of next-generation precious metals and material recovery methods are always a priority. Tanaka also has the technology to refine platinum group metals, which are often difficult to recycle.

By combining three key aspects of a successful precious metals recycling operation—assaying capabilities, recycling and fabrication processes, and product diversity—Tanaka offers sustainable, cost-effective solutions that are powering the auto industry for today and beyond.

Additional Resources

Read this research-based article to learn about consumer findings on EVs and what they mean for manufacturers.

Precious Metals and the Future of Vehicles

Watch this video to learn how vehicles are becoming more comfortable and safe due in large part to precious metals.

Environmentally Friendly Vehicles

Watch this video to learn how precious metals will be used for vehicles while complying with environmental regulations.

“Originally published in IndustryWeek”

![]()