CLOSE

About Elements

TANAKA is a leading company in the field of precious metals.

Advanced materials and solutions that support societal progress, the development stories behind them, the voices of engineers, and our management philosophy and vision—

Elements is an online media platform that shares insights that lead to a better society and a more prosperous future for the planet under the slogan “Mastering Precious Metals.”

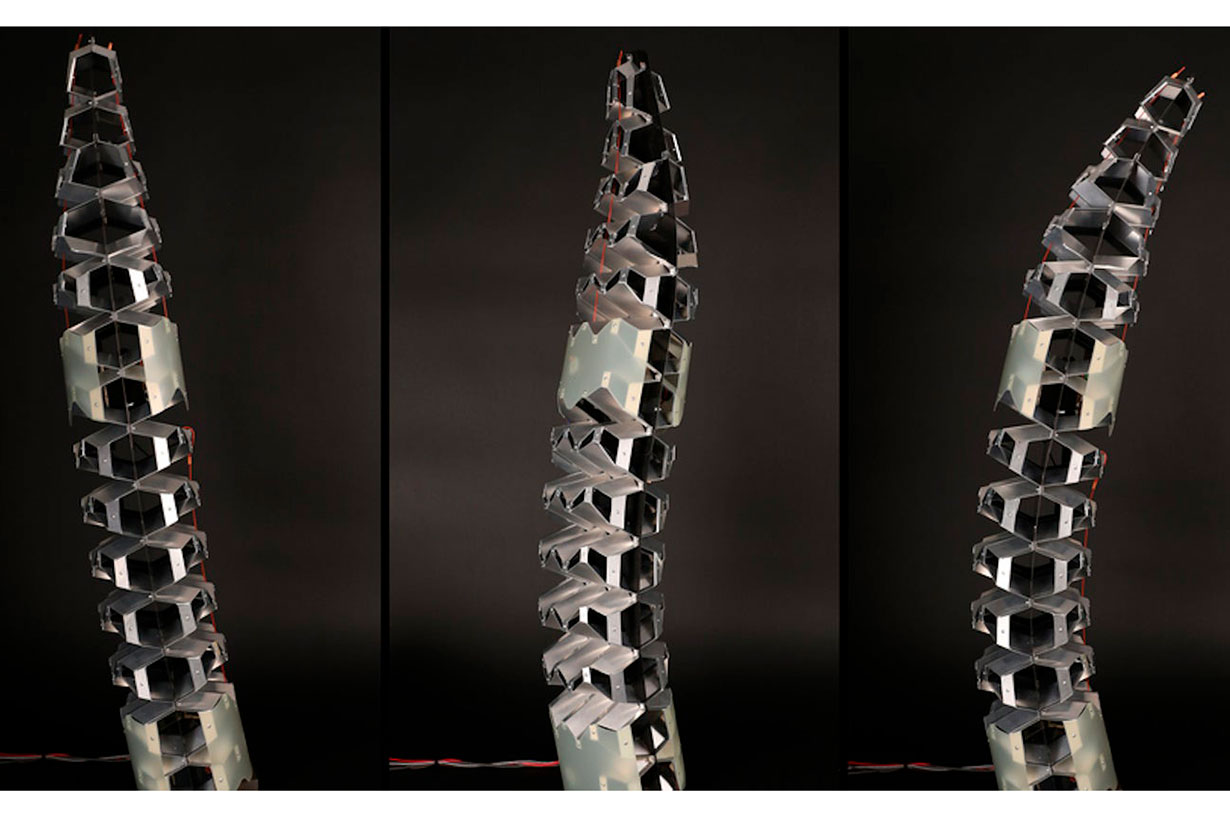

The latest kirigami-inspired engineering materials are also works of art

The ancient Japanese paper art form continues to inspire engineering breakthroughs. Top Image Credit: MIT

The ancient Japanese art of paper folding and cutting known as kirigami has increasingly inspired a new generation of engineering materials, resulting in strikingly beautiful and resilient designs. The latest iteration, courtesy of researchers at MIT, adds attributes found in both honeycomb and human bones to further strengthen advanced architectural materials, as well as potentially boost the resilience of certain airplanes, spacecraft, and robots.

As detailed in a new paper to be presented at American Society of Mechanical Engineers’ upcoming Computers and Information in Engineering Conference, the team at MIT’s Center for Bits and Atoms (CBA) developed a novel method to manufacture plate lattices—high-performance materials useful in automotive and aerospace designs. “This material is like steel cork. It is lighter than cork, but with high strength and high stiffness,” explains Neil Gershefeld, the paper’s senior author and lead researcher at MIT’s Center for Bits and Atoms (CBA).

To achieve their breakthrough, engineers altered a traditional origami Miura-ori crease already used in creating plate lattices for “sandwich structures,” which place a corrugated core between two flat plates. Although standard plate lattice sandwich structures are often made with slow, costly, and difficult adhesive and welding, the team modified a Miura-ori design’s sharp angles into facets, allowing for plate attachments via rivets and bolts. This altered design can be further customized via different creasing patterns and shapes to hone specific stiffness, flexibility, and strength—much like cellular shapes found within bones and honeycombs.

[Related: Origami-inspired robot can gently turn pages and carry objects 16,000 times its weight.]

According to the team’s findings, the kirigami-augmented plate lattices withstood three times as much force as standard aluminum corrugation designs. Such variations show immense promise for lightweight, shock-absorbing sections needed within cars, planes, and spacecraft.

“Plate lattices’ construction has been so difficult that there has been little research on the macro scale,” explained Alfonso Parra Rubio, a co-lead author of the paper and a research assistant in the CBA. “We think folding is a path to easier utilization of this type of plate structure made from metals.”

To demonstrate both the kirigami-inspired structural and artistic capabilities, some of the team’s graduate students even designed a trio of large, three-dimensional sculptures currently on display in the MIT Media Lab. “At the end of the day, the artistic piece is only possible because of the math and engineering contributions we are showing in our papers,” said Parra Rubio. “But we don’t want to ignore the aesthetic power of our work.”

For the time being, the new plate lattice manufacturing method remains difficult to model ahead of construction. Going forward, however, the team intends to build user-friendly CAD tools to streamline and simplify the kirigami lattice design process. According to MIT’s announcement on Tuesday, they also hope to investigate ways to reduce the computational costs that go into simulating designs ahead of production.

This article was written by Andrew Paul from Popular Science and was legally licensed through the DiveMarketplace by Industry Dive. Please direct all licensing questions to legal@industrydive.com.

![]()