CLOSE

About Elements

TANAKA is a leading company in the field of precious metals.

Advanced materials and solutions that support societal progress, the development stories behind them, the voices of engineers, and our management philosophy and vision—

Elements is an online media platform that shares insights that lead to a better society and a more prosperous future for the planet under the slogan “Mastering Precious Metals.”

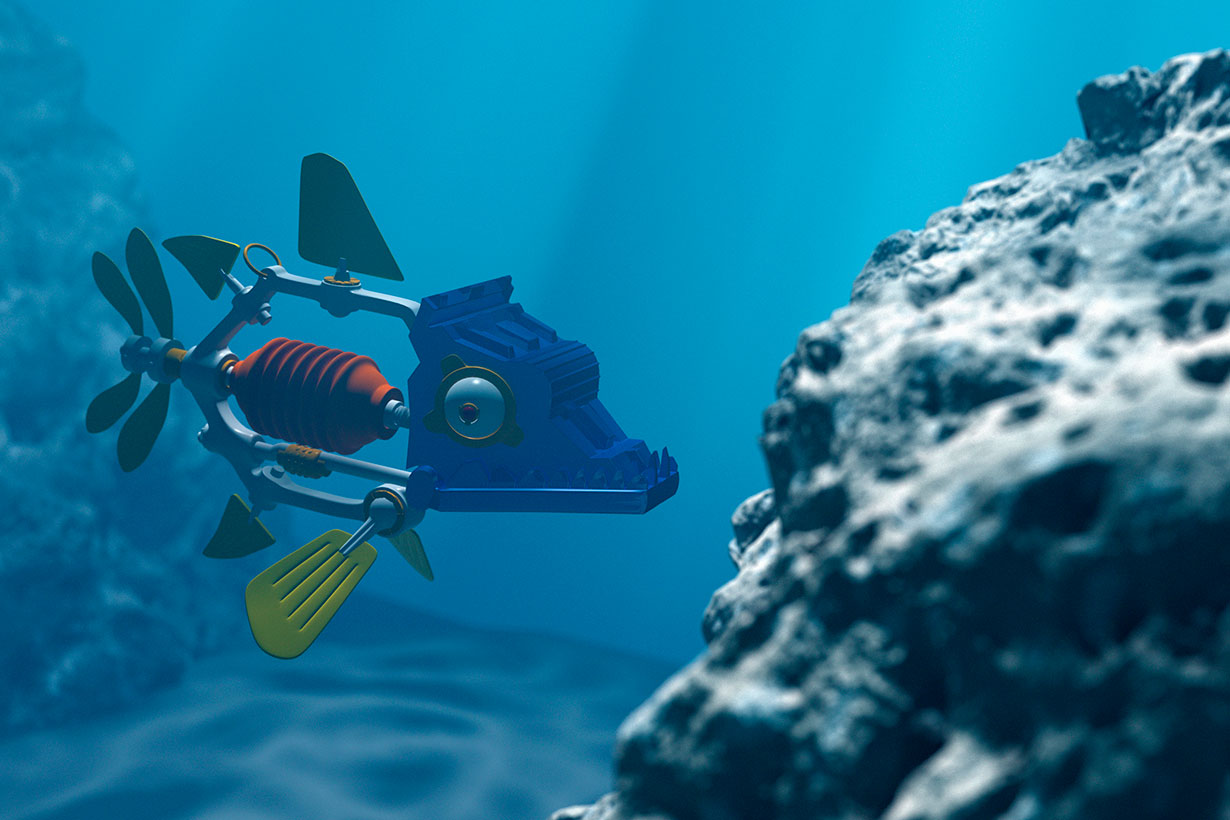

Scientists unveil bionic robo-fish to remove microplastics from seas

Scientists have designed a tiny robot-fish that is programmed to remove microplastics from seas and oceans by swimming around and adsorbing them on its soft, flexible, self-healing body.

Microplastics are the billions of tiny plastic particles which fragment from the bigger plastic things used every day such as water bottles, car tyres and synthetic T-shirts. They are one of the 21st century’s biggest environmental problems because once they are dispersed into the environment through the breakdown of larger plastics they are very hard to get rid of, making their way into drinking water, produce, and food, harming the environment and animal and human health.

“It is of great significance to develop a robot to accurately collect and sample detrimental microplastic pollutants from the aquatic environment,” said Yuyan Wang, a researcher at the Polymer Research Institute of Sichuan University and one of the lead authors on the study. Her team’s novel invention is described in a research paper in the journal Nano Letters. “To the best of our knowledge, this is the first example of such soft robots.”

Related: Robo-penguin: how artificial birds are relaying the secrets of ocean currents

Researchers at Sichuan University have revealed an innovative solution to track down these pollutants when it comes to water contamination: designing a tiny self-propelled robo-fish that can swim around, latch on to free-floating microplastics, and fix itself if it gets cut or damaged while on its expedition.

The robo-fish is just 13mm long, and thanks to a light laser system in its tail, swims and flaps around at almost 30mm a second, similar to the speed at which plankton drift around in moving water.

The researchers created the robot from materials inspired by elements that thrive in the sea: mother-of-pearl, also known as nacre, which is the interior covering of clam shells. The team created a material similar to nacre by layering various microscopic sheets of molecules according to nacre’s specific chemical gradient.

This made them a robo-fish that is stretchy, flexible to twist, and even able to pull up to 5kg in weight, according to the study. Most importantly, the bionic fish can adsorb nearby free-floating bits of microplastics because the organic dyes, antibiotics, and heavy metals in the microplastics have strong chemical bonds and electrostatic interactions with the fish’s materials. That makes them cling on to its surface, so the fish can collect and remove microplastics from the water. “After the robot collects the microplastics in the water, the researchers can further analyse the composition and physiological toxicity of the microplastics,” said Wang.

Plus, the newly created material also seems to have regenerative abilities, said Wang, who specialises in the development of self-healing materials. So the robot fish can heal itself to 89% of its ability and continue adsorbing even in the case it experiences some damage or cutting – which could happen often if it goes hunting for pollutants in rough waters.

This is just a proof of concept, Wang notes, and much more research is needed – especially into how this could be deployed in the real world. For example, the soft robot currently only works on water surfaces, so Wang’s team will soon be working on more functionally complex robo-fish that can go deeper under the water. Still, this bionic design could offer a launchpad for other similar projects, Wang said. “I think nanotechnology holds great promise for trace adsorption, collection, and detection of pollutants, improving intervention efficiency while reducing operating costs.”

Indeed, nanotechnology will be one of the most important players in the fight against microplastics, according to Philip Demokritou, the director of the Nanoscience and Advanced Materials Research Center at Rutgers University, who was not involved in this study.

Demokritou’s lab also focuses on using nanotechnology to get rid of microplastics from the planet – but instead of cleaning them up, they are working on substituting them. This week, in the journal Nature Food, he announced the invention of a new plant-based spray coating which can serve as an environmentally friendly alternative to plastic food wraps. Their case study showed that this starch-based fibre spray can fend off pathogens and guard against transportation damage just as well, if not better, than current plastic packaging options.

“The motto for the last 40 to 50 years for the chemical industry is: let’s make chemicals, let’s make materials, put them out there and then clean the mess 20, or 30 years later,” said Demokritou. “That’s not a sustainable model. So can we synthesise safer design materials? Can we derive materials from food waste as part of the circular economy and turn them into useful materials that we can use to address this problem?”

This is low-hanging fruit for the field of nanotechnology, Demokritou said, and as research into materials gets better so will the multi-pronged approach of substituting plastic in our daily lives and filtering out its microplastic residue from the environment.

“But there’s a big distinction between an invention and an innovation,” Demokritou said. “Invention is something that nobody has thought about yet. Right? But innovation is something that will change people’s lives, because it makes it to commercialisation, and it can be scaled.”

This article was written by Sofia Quaglia from The Guardian and was legally licensed through the Industry Dive Content Marketplace. Please direct all licensing questions to legal@industrydive.com.

![]()