Semiconductor Fabrication and TANAKA

Since its establishment in 1885,

TANAKA has advanced hand-in-hand with Japan’s manufacturing industry as a specialist in precious metals.

Semiconductors have become an essential part of our daily lives. They power a wide range of digital devices, such as smartphones, personal computers, and social infrastructure.

TANAKA supplies the materials used in a wide range of semiconductors, from general-purpose to advanced chips.

One of our missions is to provide cutting-edge materials that maximize the potential of precious metal materials.

Another mission is to minimize costs and enhance recycling rates through the technical expertise developed over years of product development.

We will continue to develop and ensure a stable supply of advanced materials, with precious metals as the primary component. Through this, we remain dedicated to contributing to building a comfortable and prosperous society while preserving the beautiful earth in the future.

Semiconductor manufacturing process

As semiconductor device performance advances, the industry faces rising demands in thermal management, bonding reliability, and testing accuracy. TANAKA addresses these challenges with a comprehensive lineup of materials engineered for next-generation manufacturing.

Products of TANAKA

-

Precursor

We developed high-purity ruthenium and other precious metal precursors for CVD/ALD processes. In addition to a comprehensive lineup of thin film deposition equipment for semiconductors and analytical tools for evaluation, we can offer precursors that specifically meet your purposes. We have developed technologies to recycle in-process waste and used precursors to help reduce the cost of acquiring precious metals and other raw materials.

-

Sputtering target

(melting method/sintering method)Using suitable melting and sintering techniques, we provide the targets in various shapes, sizes, and alloy compositions to meet specific application needs. We have a proven track record of producing high-purity, high-grade products ideal for semiconductors. In addition to recycling used targets, we also recover precious metals from equipment and jigs.

-

Various plating processes

We propose plating characteristics suited for specific applications and a low-cost, high-productivity process. We ensure a perfect match between the various types of wafer plating equipment and chemical processes to meet a range of needs, from experimental or small-lot production to mass-production systems, and we offer them as a complete system.

-

Probe pin materials

By effectively taking advantage of platinum-based fine wires’ stable environmental resistance and electrical characteristics, we can simultaneously achieve low electrical resistivity, high bendability, and a wide range of hardness. We have a lineup of various probe pin materials. Regarding semiconductor inspection equipment, platinum-based fine wires minimize deformation caused by probe pin wear, resulting in a longer service life and reduced inspection equipment costs.

-

Bonding wire

We supply one of the world’s largest amounts of bonding wire. In addition to gold wire, we offer copper wire, silver wire, and aluminum wire, as well as other materials, and thus, we provide reliable products that match the cutting edge of constantly evolving semiconductor technology.

-

Adhesives for die bonding

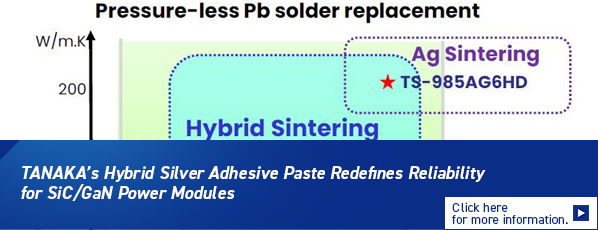

We provide conductive adhesives and a wide variety of adhesive products. For power semiconductors in particular, we offer adhesives for GaN and SiC chips, as well as solder substitutes. These adhesives are engineered to meet the need for high heat dissipation and reliability with thermal conductivity of 100 W/m-k or higher.

-

High purity deposition, bonding, and encapsulation materials

In addition to a wide range of products for joining and the hermetic sealing of precision parts, we also offer high-performance materials in wire, ribbon, pellet, block, and spherical forms. These materials are designed to minimize gas entrainment and the oxidation of additive elements. We ensure that all products meet your specific requirements.

-

Active brazing filler material

A variety of different types of ceramics, including oxides and nitrides, can be soldered without the need for metallization. We also offer materials that combine copper with active metal brazing materials, which are expected to be used in heat-dissipating components, including ceramic circuit boards for power devices and heat sinks.

-

Precious metal recycling

We use advanced recycling techniques and precious metal analysis technologies developed and refined over many years to recycle the precious metals recovered from manufacturing production scraps and used industrial products. Recycling precious metals helps customers reduce costs and supports the development of a recycling-based society.

Related materials

To learn more!

Related products

Semiconductors are continually improved to meet the demand for higher performance, including greater capacity, faster speeds, increased reliability, and reduced power consumption. TANAKA continues to support semiconductors, the foundation of advanced technologies, with a diverse range of products.