- (*)Source: SEMI Global Semiconductor Packaging Materials Outlook – 2024 Edition

Core Technologies

Technologies Created by Handling Precious Metals

Through the manufacturing of bonding wires, TANAKA ELECTRONICS has developed advanced metal processing technologies, such as gold (Au), silver (Ag), copper (Cu), and aluminum (Al) ultra-fine wires, precious metal coatings, high-purity melting, and micro-rolling. TANAKA ELECTRONICS will employ these technologies to contribute to fields such as jewelry, medical, automobile, next-generation communications, and energy saving.

■Ultra-Fine Wire

TANAKA ELECTRONICS’s area of specialization is drawing ultra-fine precious metal wire. Drawing is a processing technique in which a metal material is pull through a tool known as die and make it thinner into a wire shape. We use proprietary drawing technology accumulated over many years and uses dozens of dies to painstakingly reduce the diameter of wire, achieving precious metal wire drawing with diameters as small as 10 µm. In combination with original winding technology, we can product ultra-fine wire with a length in excess of 5,000 m.

■High-Purity Melting

Proprietary melting technology enables us to manufacture high-purity alloys by introducing additive elements on the ppm level. In addition, we use original vacuum melting technology to provide high-purity materials. We control crystalline structures through optimization of drawing and heat treatment processes and can provide products with extremely high uniformity, even minute wires with diameters of tens of microns.

■Micro-Rolling

Rolling is a process in which a meal material is introduced to rotating rollers to manufacture a thin, flat ribbon material. By using proprietary technology for rolling wire ranging from 100 µm to 600 µm, we are able to produce ribbon materials with burr-less end faces that cannot be manufactured using slit processing. In addition, we provide products with semiconductor quality using mirror rolling that reduces surface irregularities to an average of 1 µm or less and surface cleanliness control equivalent to that used for bonding wires to order to meet the needs for high bondability for automotive devices.

■Precious Metal Coatings

To respond to all semiconductor mounting needs, we use proprietary processes to manufacture pure wire with precious metal coatings applied to provide various functions. For example, recently we successfully achieved dramatic improvement in the oxidation and corrosion resistance of copper wiring by applying a coating of palladium, a precious metal.

Manufacturing Processes that Support the World’s Leading Market Share

Integrated Production in Clean Rooms

All processes from melting to drawing and winding are performed in clean rooms that are rigorously managed. This makes it possible to provide extremely clean products with little surface contamination.

Bonding Wire Manufacturing Flows

-

1. Melting

In this process, high-purity metals and trace amounts of additive elements are melted and alloys with various functions are cast.

-

2. Drawing

Tools known as dies are used to make the metal thinner and draw it into wire.

-

3. Annealing

In this process, the wire is annealed to change its crystalline structure and adjust the hardness.

-

4. Coating

A coating of precious metal is applied to the wire surface to provide anti-corrosion, anti-oxidation, and other functions.

-

5. Winding

In this process, the manufactured wire is wound in a spool while taking care to minimize any damage.

TANAKA ELECTRONICS’s New Challenges

TANAKA ELECTRONICS Seeks to Create New Value Using Technologies Nurtured in the Field of Semiconductors

■Wire material for jewelry

Using our technologies and materials

not just for

semiconductors but also for jewelry

Gold bonding wires are key materials for semiconductors.

We also are using the features of high purity and quality

to provide wire materials for jewelry.

The wire’s beautiful glare and golden color

are evidence of high quality

This is a new challenge based on stable material quality.

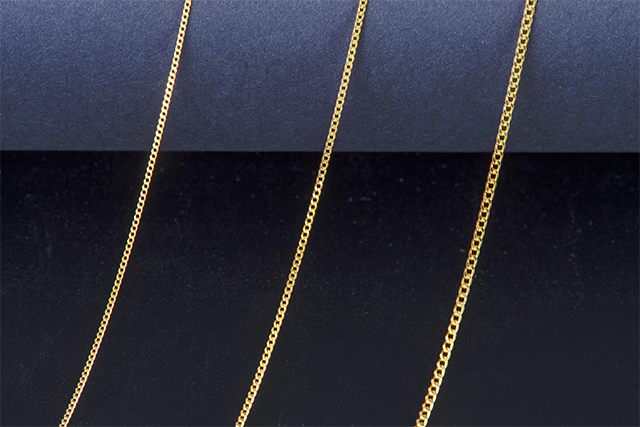

The technologies nurtured in the field of semiconductors were

used to turn wire materials into thin, beautiful, shiny chains.

We developed pure gold that is stronger than conventional pure gold by applying our technologies cultivated through bonding wire manufacturing

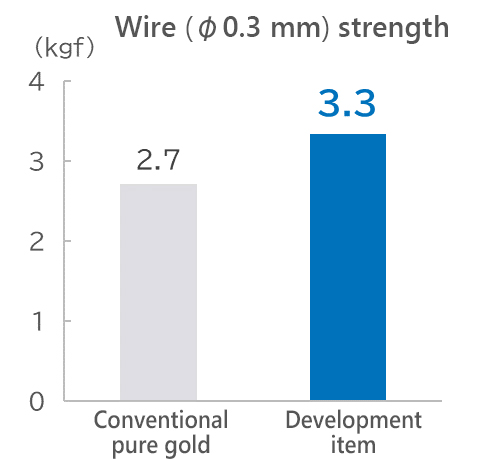

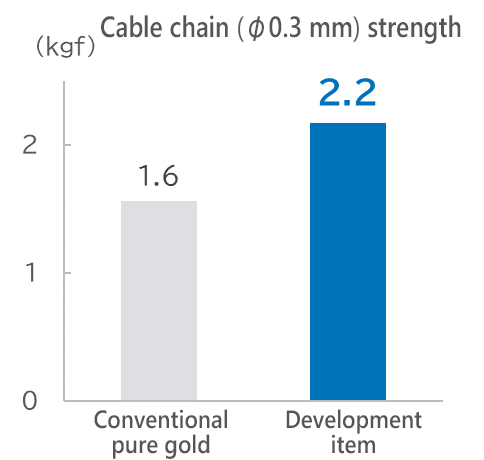

Higher wire strength

than conventional pure gold

Conventional pure gold is soft and it cannot be used for products that require strength

We successfully developed high-purity and high-strength pure gold by applying our technologies cultivated through bonding wire manufacturing

Reference value: Φ0.3 mm chain strength

Increased chain strength compared to conventional products

We provide stable Au wire by applying our manufacturing technologies cultivated through bonding wire manufacturing.

Customers’ comments

A retail store

The pure gold necklace, made with the new material, has higher hardness and tensile strength than conventional materials, which made it possible to produce products with pieces that are fine but highly resistant to deformation and breaking. This property allows us to offer several designs of pure gold chains, from a simple standard product to a product with a gorgeous design.

Customers can enjoy the beauty and brilliance of the precious metal itself. In addition, the gold chains can be used daily at ease thanks to their higher strength than conventional gold chains. This point is also a deciding factor for the customers in their purchases.

A wide range of customers select the necklace since it can be worn alone as a chain necklace or with a pendant top.

As of the end of November 2024, the sales volume increased approximately 2.5 times over the previous year.

A chain manufacturer

Furthermore, the chain-forming property is excellent and there was not a single abnormal stop of the chain production machine. We have never experienced this before when using pure gold.

A chain manufacturer

■Wire Rods for Medical Applications

Soft gold wire is an optimal precious metal wire for use as a marker in minimally invasive procedures such as catheterization and with guide wires. To enhance the accuracy of radiation therapy, we provide high-purity, high-strength gold wire that X rays do not easily pass through, making it highly visible.

Features

- ○High purity (at least 99.99%)

- ○High X ray impermeability

- ○Low contamination

- ○Wire diameters from 10 µ to 100 µm

- ○High biological safety (unsafe elements are not used)

※The purity, diameter, and other parameters can be customized.

Please inquire.

■Ultra-Small Gold (Au) Pin (Φ60 um×L55 um)

As gold wires of high purity are soft, it is difficult to make ultra-small pins through cutting. Our gold wires can be used to manufacture ultra-small pins with diameters down to Φ60 um while having a purity of 99.99%. We can provide small samples for tests.

Features

- ○High purity (at least 99.99%)

- ○Low contamination

- 〇Small tolerance of cutting length

※ As this product is still being developed, please inquire about details such as other types of metals, including alloys, and dimensions.

■The Future that TANAKA ELECTRONICS Sees: Entering New Business Fields

Solving Customer Problems Through Product Development: Examples of Solutions from TANAKA ELECTRONICS

-

80% Reduction in Material Costs with Silver Bonding Wire

With just a small capital investment, material costs can be reduced by 80%.Silver bonding wire exhibits excellent durability, conductivity and speed of production.

Chipmaker;E Inc. -

Copper Bonding Wire With Better Performance than Gold

Use of copper bonding wire reduces material costs by 90% to resolve the issue of steeply rising gold prices impacting profits.

Chipmaker;M Inc.