Recovery and Refining

Based on “Reliability,” “Confidence,” and “Technology,” we offer a one-stop recycling system for precious metals, from recovery and refining to remanufacturing.

TANAKA efficiently recycles precious metals—rare and valuable resources—to contribute to the development of a sustainable society.

Features

- High extraction technology and accurate evaluation

- Flexible account settlement system, including purchasing, bullion return and recovery as precious metal products

- Strict confidentiality on recovered materials

- Preprocessing technology and processing equipment which are adapted for any form of scrap metal

- Precious metal separation technology and precision cleaning technology from sputtering equipment and vapor deposition equipment

- Provision of precious metal recovery equipment (electrolysis equipment, ion exchange resin equipment, activated carbon filter etc.)

Certifications

- Certified as a “Good Delivery Referee” by the London Bullion Market Association (LBMA)

- Certified as a “Good Delivery Referee” by the London Platinum and Palladium Market (LPPM)

- Certified melter of gold (the first in Japan) and silver at the London market

- Good delivery bar in platinum and palladium by the LPPM

- Recognized as a “Good Delivery” brand for gold bullion by the New York Commodity Exchange, Inc (COMEX)

- Certified melter of platinum and palladium by the New York Mercantile Exchange (NYMEX)

- ISO9001, 14001, and OHSAS18000 certified

Types of Precious Metal Recovery

Solid recovery

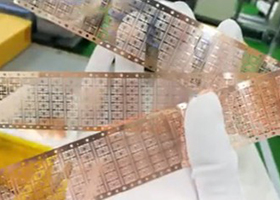

![]() Recovery from scrap

metal containing precious metals

Recovery from scrap

metal containing precious metals

- Used targets

- Printed wiring boards

- ICs

- Ceramic package

- Used catalysts

- Scrap from ornament processing

- Used paste, etc.

Liquid recovery

![]() Recovery from waste

liquid containing precious metals

Recovery from waste

liquid containing precious metals

- Waste plating solution

- Other liquids containing precious metals

Sales of equipment

![]() Precious metal recovery

equipment

Precious metal recovery

equipment

- RECOVER CELL

- EAGLE-RE

- EAGLE-AC

-

Printed wiring boards

-

Ceramic package

-

Lead frame

-

Jewelry

-

Waste plating solution

Precision Cleaning of Precious Metal Adhering to Jigs, and Precious Metal Recovery.

- We offer precision cleaning technology for reliable evaluation of precious metal adhering to the surface of sputtering or vapor equipment

- Thin-film removal technique using our proprietary chemical solvents designed to minimize damage to jigs

- Precious metal evaluation assured with trustworthy analytical technology.

- Recovered precious metals from jigs are effectively used as deposition ingredients such as targets or vapor deposition materials

Overview of Precision Cleaning and Precious Metal Evaluation Process

![[Explanatory diagram of Precision Cleaning and Precious Metal Evaluation Process] Solvents containing precious metals are filtered and preprocessed with our advanced pretreatment technique for the recycling of homogeneously distributed materials.](https://prod-cms-cache-bucket.s3-ap-northeast-1.amazonaws.com/wp-content/uploads/sites/images/ex/en/products/images/g01/img_block02_01.jpg)

Sputtering equipment

at our plant

Gold target

Flowchart of Recovering and Refining Precious Metals