Palladium-Coated Copper Bonding Wires (PCC Bonding Wires)

Obtaining advantage in both cost and performance

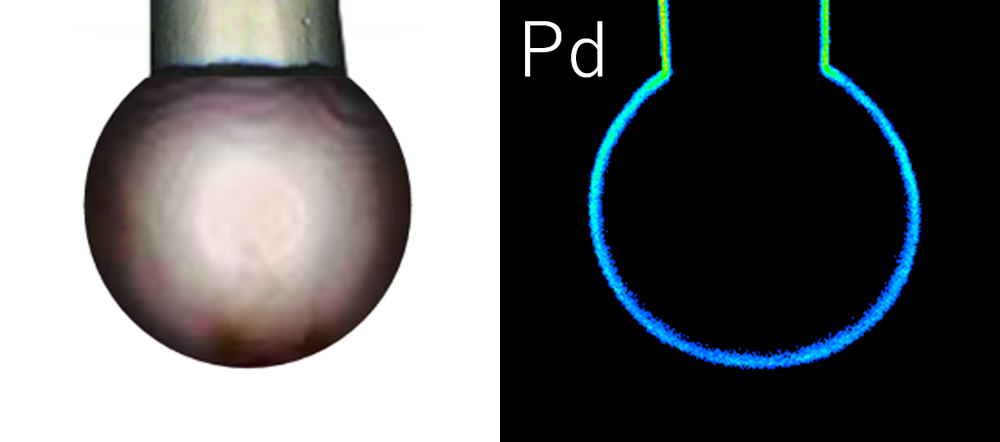

It is a copper bonding wire covered with palladium on the wire surface.

Cost reduction is achieved with high bonding properties and bonding reliability.

CHR-1BK (Standard PCC Bonding wires that meet the needs for high reliability)

■Features

- High bonding reliability is obtained by stable palladium distribution to FAB surface layer

- High and stable stitch bondability

- Wide bonding window

■Reliability

Three types of reliability evaluation shown in the table below are widely used to check the reliability of interconnecting components using copper wiring in automotive products.

Evaluation is conducted under AEC-Q006 Grade0 standard and items that satisfy the criteria are marked in blue.

HTSL: High Temperature Storage Life

uHAST: unbiased Highly Accelerated Stress Test

TCT: Temperature Cycling Test

| Wire | HTSL | uHAST | TCT |

|---|---|---|---|

| Bare Cu | 1,000hr | 192hr | < 2,000 cyc |

| Conventional PCC | 1,500hr | 500hr | < 2,000 cyc |

| High Reliability PCC CHR-1BK |

< 3,000hr | < 1,000hr | < 2,000 cyc |

*AEC-Q006 Grade0 standard

HTSL: 175degC 2000hr

uHAST: 130degC 85%rh 192hr

TCT: -65degC 150degC 1500cyc