Bonding Wires

World’s Largest Provider(*)

TANAKA’s Bonding Wires

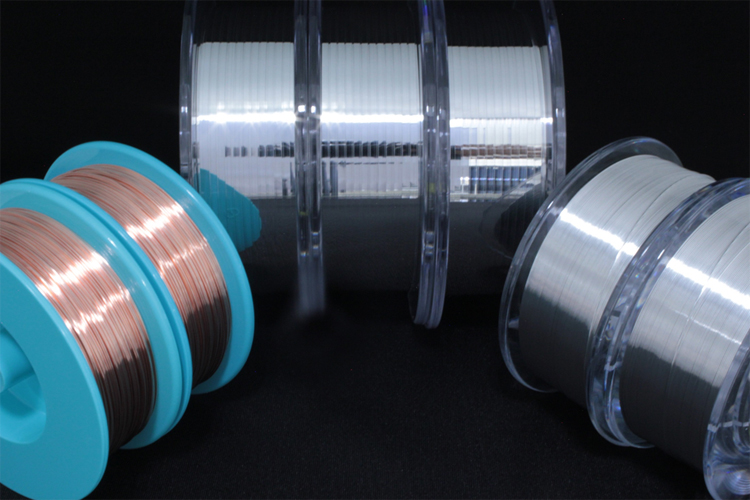

TANAKA offers bonding wires and ribbons, such as gold (Au), silver (Ag), copper (Cu), and aluminum (Al) ultra-fine wires (10 to 38µm) as metal bonding materials and thick wires (100 to 500um) for power devices. Wires with smooth and clean surfaces that have excellent dimensional stability are provided together with solutions that include expertise on metal bonds.

- (*)Source: SEMI Global Semiconductor Packaging Materials Outlook – 2024 Edition

Gold and Gold Alloy Bonding Wires

More than 50 Years of Trust and Experience

Gold (Au) and gold alloy bonding wires with high performance continue to support the semiconductor industry. They boast chemical stability and excellent electrical conductivity not found in other metals. Through material development, we can achieve functions such as fine pitch and low loop while maintaining high purity.

Silver Alloy Bonding Wires

Giving Form to the Technologies of a precious Metal Maker

Silver (Ag) alloy bonding wires have excellent electrical and thermal conductivity. They are also effective wires for optical semiconductor devices such as LEDs as they have high reflectivity in the visible spectrum. In addition, as an alternative material for gold (Au) wires, costs can be reduced by approximately 80%.

Copper and Copper Alloy Bonding Wires

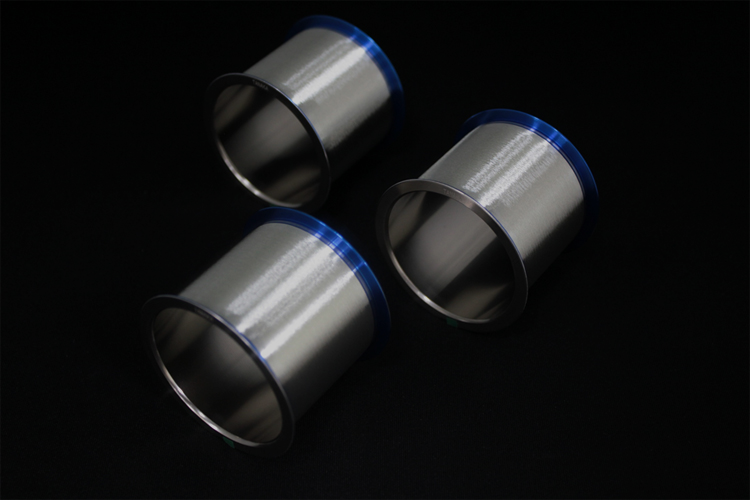

Aluminum and Copper Bonding Wires for Power Devices

The Standard for Power Devices

TANAKA ELECTRONICS offers high-purity aluminum (Al) and copper (Cu) bonding wires (100 to 500µm) and ribbons (width 0.5 to 2.0mm) with excellent surface properties of automotive grade. As aluminum has excellent moisture resistance , it is often used in power device applications that drive high currents under harsh environments. We also have wires for power devices that use copper, which has even better electrical conductivity.

Palladium-Coated Copper Bonding Wires (PCC Bonding Wires)

List of Types

| Fine Wire

(14um~80um) |

Thick Wire

(φ100µm~500µm) |

Ribbon | |

|---|---|---|---|

| Gold |

|

|

|

| Silver |

|

|

|

| Copper |

|

|

|

| Aluminum |  |

|

|

|

Palladium

Coated Copper |

|

|

|

* Please inquire regarding product and development items for which detailed information is not provided on this site.

Results of wire and bonded material combinations

| Bonding | Bonded Material | ||||||

|---|---|---|---|---|---|---|---|

| Al | Au/Pd/Ni

Plating |

Ag

Plating |

Ni

Plating |

Cu | |||

| Wire | Au/Au Alloy | Ball bonding | ★★★ | ★★★ | ★★★ | ☆☆☆ | ★☆☆ |

| PCC | Ball bonding | ★★★ | ★★★ | ★★★ | ☆☆☆ | ★☆☆ | |

| Cu/Cu Alloy | Ball bonding | ★★★ | ★☆☆ | ★★★ | ☆☆☆ | ★☆☆ | |

| Ag Alloy | Ball bonding | ★★★ | ★★★ | ★★★ | ☆☆☆ | ☆☆☆ | |

| Cu | Wedge bonding | ★☆☆ | ☆☆☆ | ☆☆☆ | ★☆☆ | ★★★ | |

| Al | Wedge bonding | ★★★ | ★☆☆ | ☆☆☆ | ★★★ | ★★☆ | |

★: Based on combinations of market results known to us.

★★★ Considerable results in the market

★★☆ Results in the market

★☆☆ Almost no results in the market

☆☆☆ No results in the market

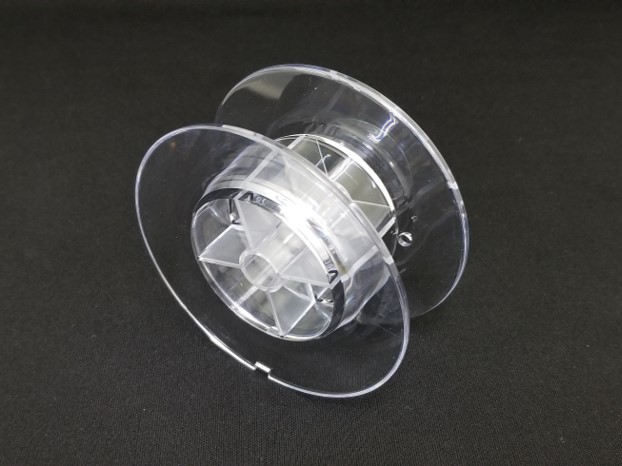

Stadards of Spool for Bonding Wire

For Fine Bonding Wire

| Type | Material | A | B | C | D | E | F |

|---|---|---|---|---|---|---|---|

| AL-4 | Aluminum | 58.5 | 48.8 | 50.3 | 0.75 | 45.5 | 47 |

For Wire and Ribon for Power Devices

| Type | Material | A | B | C | D | E | F |

|---|---|---|---|---|---|---|---|

| No.88 | Poly Carbonate | 88 | 10 | 50 | 3 | 25 | 31 |

| No.88B | 89 | 10 | 71 | 3 | 25 | 31 | |

| No.88K | 88 | 11 | 50 | 3 | 31 | 37 | |

| No.120 | 120 | 10 | 54 | 4 | 30 | 38 | |

| No.120K | 120 | 11 | 64 | 4 | 30 | 38 |

-

-

Al-4 -

No.88

No.88B -

No.88K

No.120K

*Please inquire about other specifications.

Physical Characteristics (data for use with simulations) * Reference values

| Unit | Gold | Copper | Aluminum | Silver | Palladium | Platinum | |

|---|---|---|---|---|---|---|---|

| Atomic symbol | Au | Cu | Al | Ag | Pd | Pt | |

| Atomic number | 79 | 29 | 13 | 47 | 46 | 78 | |

| Atomic weight | 196.96655 | 63.546 | 26.981538 | 107.8682 | 106.42 | 195.078 | |

| Crystal structure | fcc | fcc | fcc | fcc | fcc | fcc | |

| Lattice constant | Å | 4.0785 | 3.6147 | 4.0496 | 4.0862 | 3.8907 | 3.924 |

| Melting point | K | 1336.15 | 1356.45±0.1 | 933.25 | 1233.95 | 1825.15 | 2042.15±1 |

| Boiling point | K | 2983 | 2855 | 2750±50 | 2423±20 | 3150±100 | 4100±100 |

| Density (20℃) | g・cm -3 | 19.32 | 8.92 | 2.70 | 10.50 | 12.02 (22℃) | 21.45 |

| Resistivity (20℃) | µΩ・cm | 2.3 | 1.694 | 2.7 | 1.63 | 10.8 | 10.58 |

| Heat of fusion | kJ・mol -1 | 12.37 | 13.1 | 8.40±0.16 | 11±0.5 | 16.7 | 19.7 |

| Thermal conductivity

(0~100℃) |

W・m -1・K -1 | 315.5 | 397 | 238 | 425 | 75.2 | 73.4 |

| Specific heat

(0~100℃) |

J・kg -1・K- -1 | 130 | 386.0 | 917 | 234 | 247 | 134.4 |

| Coefficient of

linear expansion (0~100℃) |

x 10 -6・K -1 | 14.1 | 17.0 | 23.5 | 19.1 | 11.0 | 9.0 |

| Young’s modulus |

GPa | 88.3 (300K) |

136 (298K) |

69 (300K) |

100.5 (300K) |

121 (293K) |

169.9 (293K) |

| Shear modulus |

GPa | 29.6 | 26.0 | 31.3 | |||

| Poisson’s

ratio |

0.440 | 0.343 | 0.345 | 0.367 | 0.393 | 0.377 |

* We can also provide products that use recycled gold as raw material in accordance with customer needs.