Active Brazing Filler Metals

Bonding of various ceramics

Our active brazing filler metals enable brazing of various ceramics, regardless of whether they are oxides or nitrides, without metallization.

We also provide composite materials of copper and active brazing filler metals that are expected to be used for applications such as ceramic circuit boards, and heat dissipation parts such as heat sinks, for power devices.

Active Brazing Filler Metals

Features

- Active brazing filler metals are brazing fillers with added titanium (Ti) to enable direct brazing of ceramics, which cannot be bonded using general brazing fillers.

- They enable brazing of a range of materials, including alumina and other oxide ceramics, silicon nitride, and carbon.

- A unique alloy composition with added tin (Sn) enables fine dispersion of titanium when added to brazing fillers.

This enables provision in sheet thicknesses of 50 µm.

Sheet cross section structure

AgCuTi alloy

Large particles of CuTi compound within the AgCu matrix

AgCuSnTi alloy

Thin sheet manufacture and supply enabled by fine dispersion of SnTi compound

Types

| Product | Main component (wt%) | |||

|---|---|---|---|---|

| Ag | Cu | Ti | Sn | |

| TKC-661 | 66 | 29.5 | 1.5 | Bal. |

Physical properties

| Material | TKC-661 | (comparable product) BAg-8 |

|---|---|---|

| Specific gravity | 9.7 | 10.0 |

| Solidus (℃) | 745 | 780 |

| Liquidus (℃) | 780 | 780 |

| Hardness (HV) | 113 | 90 |

| Tensile strength (MPa) | 356 | 294 |

| Young’s modulus (GPa) | 85.0 | 97.0 |

| Coefficient of linear expansion (×10-6/℃) | 18.6 | 17.1 |

| Thermal conductivity (W/mK) | 102.0 | 311.0 |

| Ceramic bonding | 〇 | × |

Product format

| Form | Dimensions |

|---|---|

| Wire | Diameter: 0.2 mm or more |

| Sheet | Width: 120 mm or less Thickness: 160 mm or less |

![[Product format of Active Brazing Filler Metals] Sheet and Wire](https://prod-cms-cache-bucket.s3-ap-northeast-1.amazonaws.com/wp-content/uploads/sites/images/ex/en/products/images/c04/img_block01_03.jpg)

Bonding examples

Alumina-to-alumina bond :

830℃ vacuum brazing

Silicon nitride-to-silicon nitride bond : 830℃ vacuum brazing

4-point bending test results (alumina)

Exterior of test piece![[4-point bending test results(alumina)]Exterior of 4-point bending test piece and fractured test piece](https://prod-cms-cache-bucket.s3-ap-northeast-1.amazonaws.com/wp-content/uploads/sites/images/ex/en/products/images/c04/img_block01_06.jpg)

Fracture strength measurements

![[Comparison of fracture strengths in 4-point bending test graph]BAg-8 / TKC-661](https://prod-cms-cache-bucket.s3-ap-northeast-1.amazonaws.com/wp-content/uploads/sites/images/ex/en/products/images/c04/img_block01_07.jpg)

Comparison of fracture strengths in 4-point bending test

Bond interface fractures were observed when using BAg-8 (metalized), whereas base material fractures were observed when using active brazing filler metals.

Testing confirmed sufficient strength was achieved for bonds that use active brazing filler metals.

Cross-section observation using SEM

Results of EDX surface analysis of brazing bond interfaces:Al2O3

Titanium layers were formed at both the ceramic and brazing filler interfaces.

It is presumed that a compound layer of Al-Ti-O is formed at the interface between the titanium later and the alumina.

Active Brazing Filler Metal/Copper Composite Material

[left] Composite of copper side

[right] Composite of active brazing fillermetal side

New material will contribute to heat dissipation when used in next-generation heat sinks for power devices

The new product is a composite (cladding) of copper (Cu) material with active brazing filler metal on one side.

Since it can be joined directly to any material including ceramics (oxides, nitrides, and carbides) and carbon materials, it is expected that it will be used in ceramic substrates and next-generation heat sinks for power devices.

Features

- Improved performance

– The thick copper electrodes needed for high heat dissipation heat sinks can be formed directly on ceramics, and even finer wiring pitch is possible, which was difficult to do with existing etching processes.

– Since the material does not contain any solvents, there is no residue and bonding reliability is improved. - Cost reduction

– The brazing filler thickness can be 10 µm or less, which means that compared to earlier active brazing filler metal, silver bullion costs can be reduced by half or more and the brazing filler thermal resistance is halved.

– The copper material is compounded, which means that a pattern can be formed simply by setting the material, reducing processing costs. - Environmental impact reduction

– Since the material contains no solvents, volatile organic compounds (VOCs) are not released.

– The brazing time can be greatly reduced, which leads to energy savings and can be expected to reduce environmental impact.

– Both high heat dissipation and fewer processes possible –

Substrate model using the proposed process

![[Explanatory diagram of substrate model using the proposed process] From the top: Silicon chip, Solder, Copper, Active brazinf filler metal, Sin or AIN, Active brazing filler metal, copper, cooling device](https://prod-cms-cache-bucket.s3-ap-northeast-1.amazonaws.com/wp-content/uploads/sites/images/ex/en/products/images/c04/img_block02_02.jpg)

- Contributing to

- ・Power devices market

- ・Eco-car market (electric vehicles (EVs),

- hybrid vehicles (HVs), etc.)

- ・High-output laser diode market

- ・Next-generation heat sink market

- Higher outputs and increased efficiency are demanded, and in conjunction with this, heat generation is rising. As a result, providing individual components with high heat dissipation, high thermal resistance, and high bonding reliability, and developing materials that are compatible with even further miniaturization, are urgent priorities for the industry.

- Therefore, it is necessary to increase the thickness of the copper sheet

- This product makes it possible to form electrodes on a thick copper material and enhances bonding reliability by not using etching, so it can be expected to contribute to higher heat dissipation.

Proposed process reduction enabled by this product

The following video depicts a manufacturing process using this product.

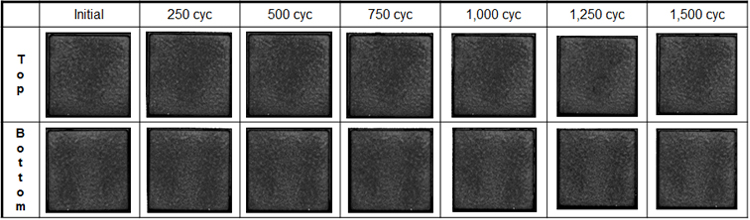

Heat cycle test results

Sample details

・Brazing filler : TKC-661 0.02mm

・Cu : 0.8 x 30 x 30mm

・Si3N4 : 0.32x 31 x 31mm

・Cu : 0.8 x 30 x 30mm

Heat cycle testing between minus 50℃ and plus 175℃ confirmed durability of at least 1,500 cycles.

Samples of this product are now available. Contact us for details.